Sustainable Energy

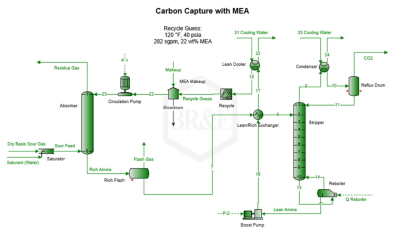

ProMax stands as the premier simulator for pre- or post- combustion capture processes, facilitating the efficient removal of CO2 from gas streams.

We can help you with modelling the following technologies used in CCS:

- Amine Sweetening using generic amines, physical solvents, and proprietary solvents

- CO2 Compression, dehydration, and injection

- CO2 Liquefaction

- Membrane separation

- Low temperature distillation

- SOx removal

- Hot Potassium Carbonate process

- And MORE!

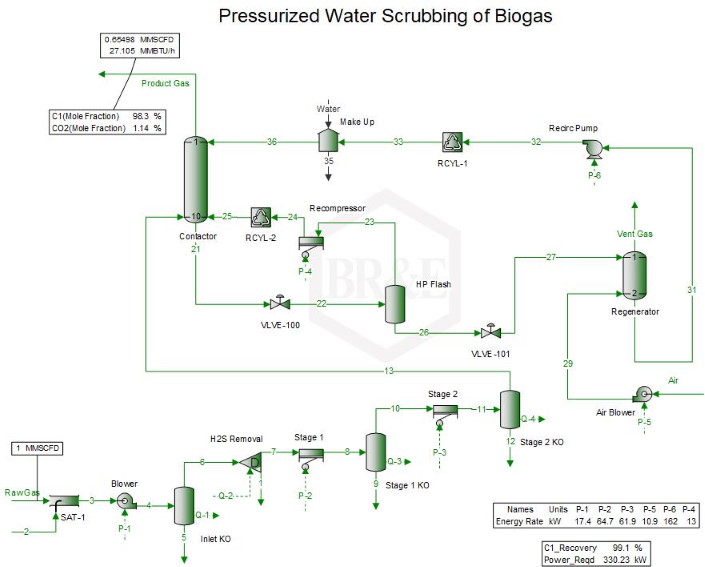

Model a variety of processes to upgrade biogas to a variety of qualities, including pipeline quality:

- Pressurized Water Scrubbing

- Membrane Separation

- Acid Gas Removal

- Sulfur Removal

- Amine Treating

- DEPG

- Cryogenic Processing

- CO2 Freeze Out

- Low Temperature Distillation

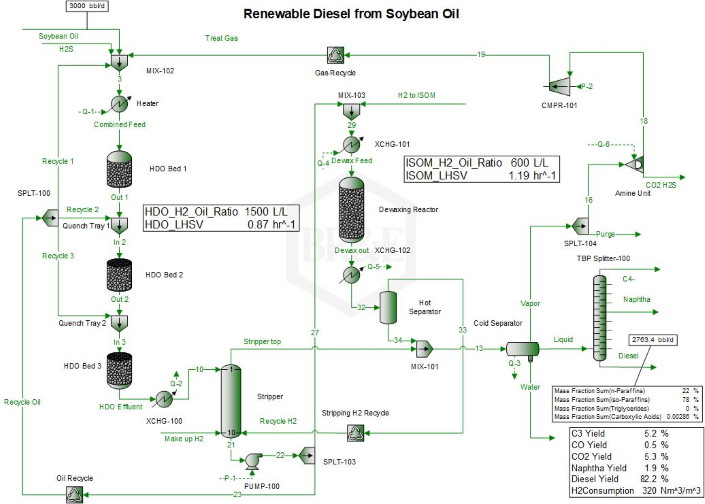

Enhances to our AutoKinetic Reactors and thermodynamic predictions allows modeling of the complete Renewable Diesel Process!

- A range of triglycerides and fatty acids

- HDO reactor with multiple pathways

- Isomerization Reactor

- Recycle Gas Treating

- Product Separation

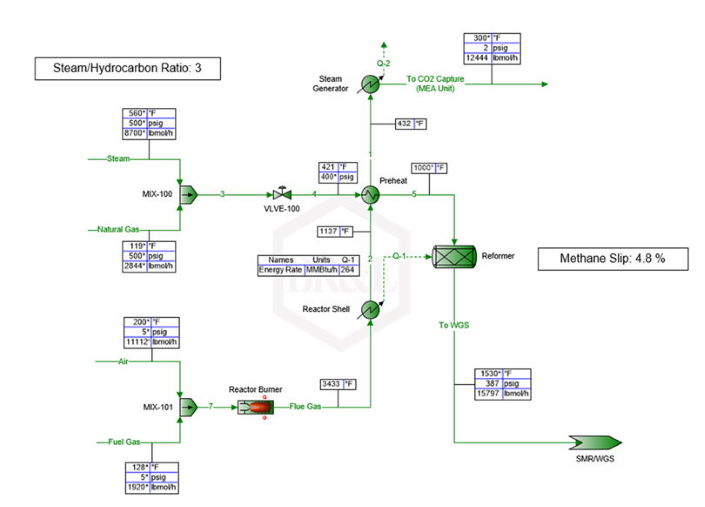

ProMax 6.0 is a great choice for simulating the various Blue Hydrogen production options which often include Carbon Capture, Utilization, and Storage (CCUS).

Relevant reacting systems below can be modeled using ProMax:

- Steam Methane Reforming with Flue Gas CO2 Capture

- Autothermal Reforming

- Pre-reforming

- Tri-reforming

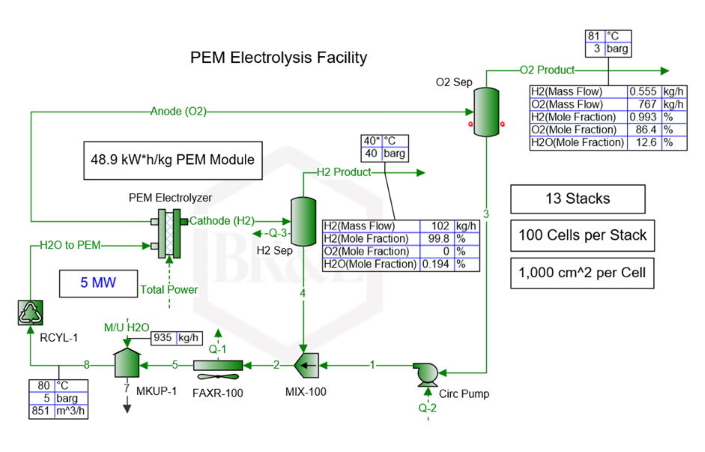

With ProMax 6.0, BR&E introduces new process blocks for simulating water electrolysis to produce Green Hydrogen:

- Polymer Electrolyte Membrane (PEM)

- Alkaline Water Electrolysis (AWE)

- Solid Oxide Electrolysis (SOE)

Many alternate combinations of properties available for solving the electrolyzer including:

- Total Power Input

- Hydrogen Production Target

- Fraction Inlet H2O Conversion

- Current Density

- Area per Cell

- Cells per Stack

- Stacks per Facility