Refining

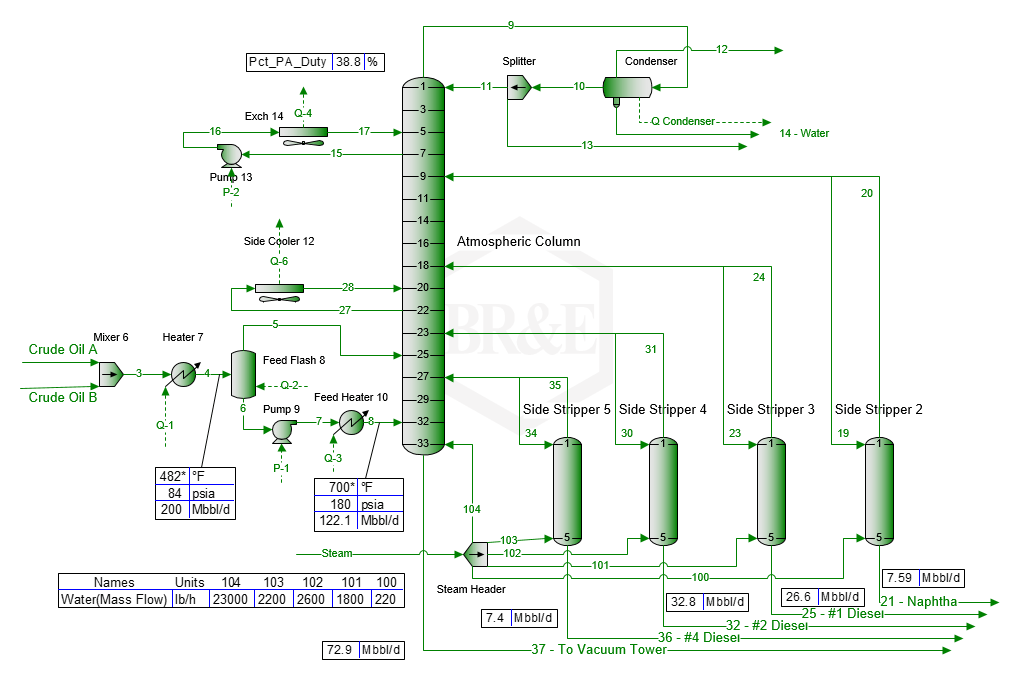

With ProMax, you can accurately model a variety of fractionation columns in refineries, including crude fractionators (atmospheric and vacuum), saturated gas plants, coker fractionators, and many others. Need to convert assay data into a mixture of compound and pure species? Our Oil Speciation Tool® allows you to do so with ease!

With accurate thermodynamics, heat exchanger rating capabilities, and calculators for fine-tuning and optimization available in the software, you have the ability to properly model heat exchanger networks, track fouling, schedule maintenance, and improve energy integration.

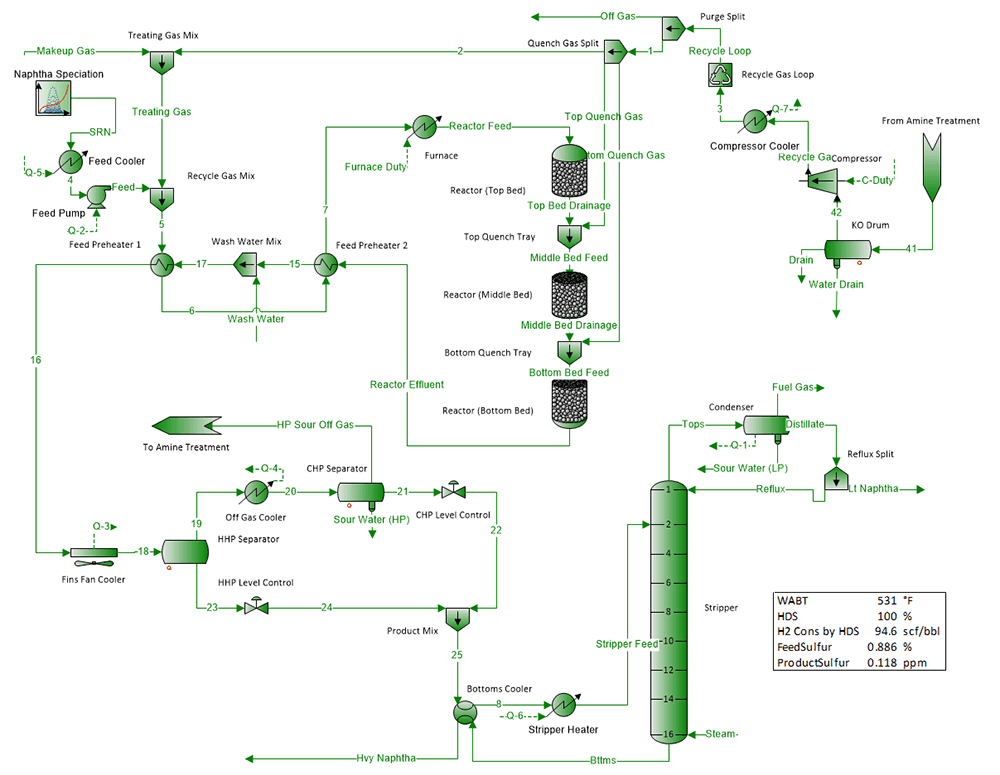

ProMax AutoKinetic® reactors provide you with a suite of rigorous reactor models to effectively simulate petroleum refining processes. These include hydrotreaters, hydrocrackers, catalytic reforming, and other hydro-processing systems.

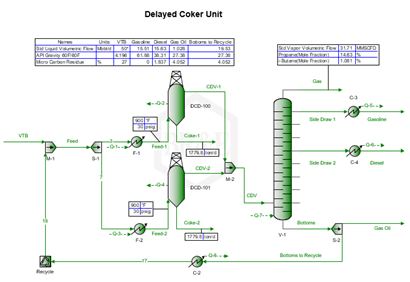

With the new Delayed Coker block in ProMax, you have the ability to optimize product yields and predict drum outage height. Unit performance can be maximized by tuning process parameters such as recycle ratio, coke drum pressure, and furnace outlet temperature.

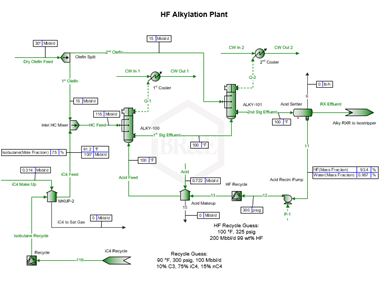

The new Alkylation block converts C3, C4, and C5 olefins into alkylate and poly-alkylation products. The block provides convenient investigation of key process parameters and seamless ties in to product separation, including iso-strippers, acid regenerators, and more.

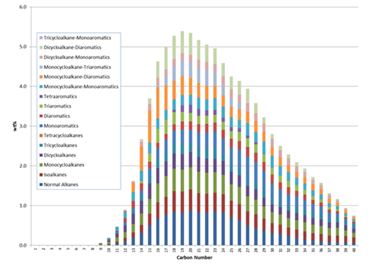

ProMax provides considerable power in characterizing the properties of complex hydrocarbon mixtures such as crude oils. Typical assay data, such as TBP or D86 curves, may be used to create curve oils. The Speciation Tool may also be used to relate a given crude to pure or compound species to reflect the class of molecules the mixture contains. User Defined properties allow even more information to be includes, such as sulfur or metals distribution.

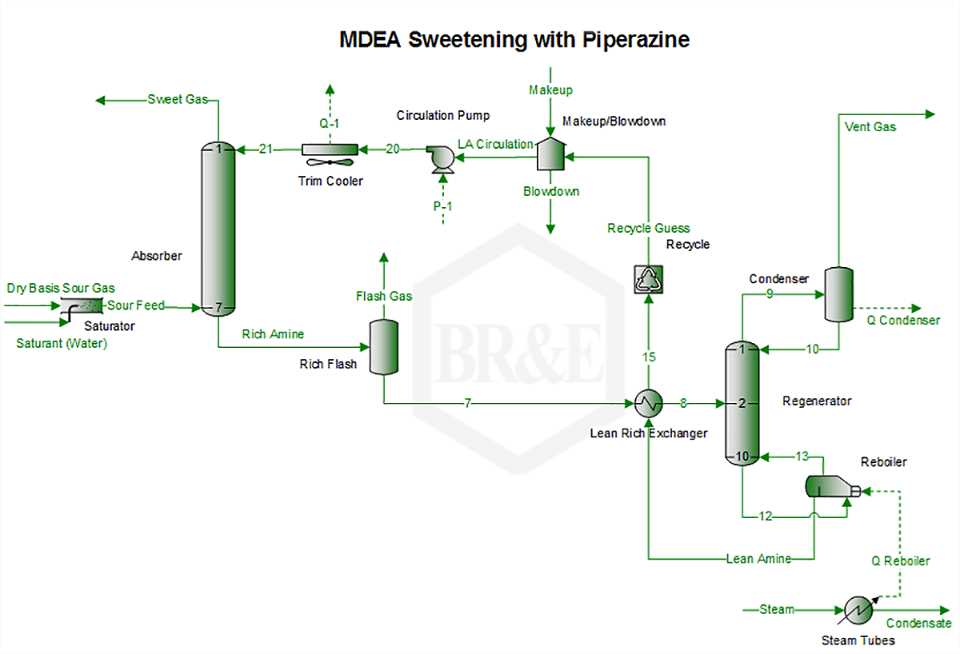

For over 40 years, BR&E has been known as the industry leader for simulating acid gas removal systems. ProMax continues this legacy and is the most versatile and complete package available for a variety of acid gas removal systems, all of which can be directly integrated with your other hydrocarbon processing systems in one simulation file!

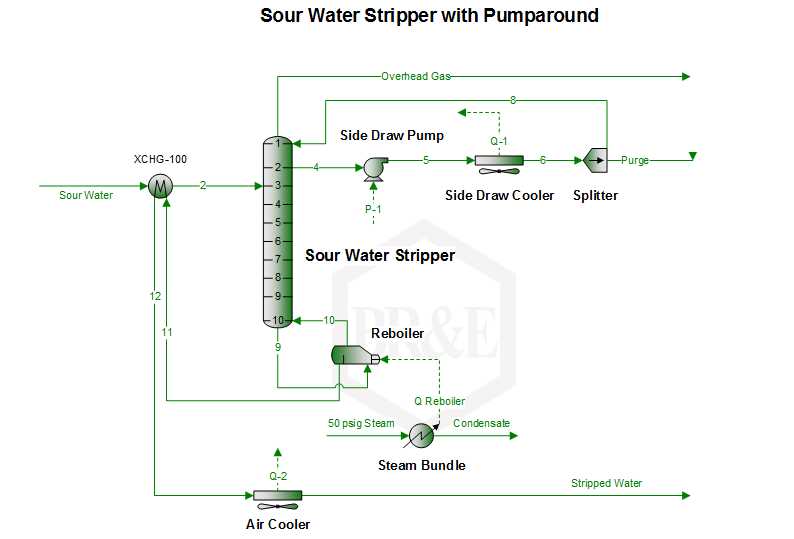

Bryan Research & Engineering's custom electrolytic property package allows you to rigorously model any sour water stripper configuration, not only for NH3 and H2S, but for trace contaminants as well such as HCN and phenols. The robust electrolytic model easily accounts for pH and the addition of acids or bases to enhance stripping.

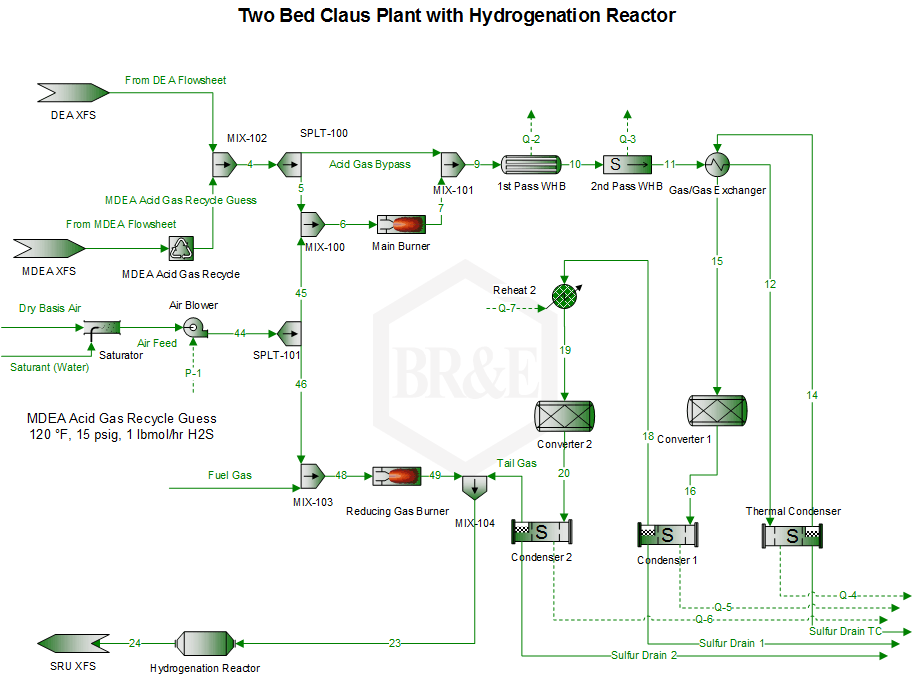

With ProMax’s complete suite of reactor models, you can easily set up an accurate model of sulfur recovery unit operations. You are able to model real world behavior using a theoretical approach with empirical modifications based on decades of experience with these systems.

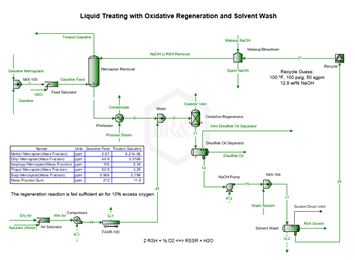

Whether multistage pump around systems for acid gas removal from ethylene to regenerative systems for mercaptans removal from hydrocarbon liquids, ProMax contains a comprehensive capability for modeling caustic systems.