Renewable Diesel

A growing area in the transportation segment is “Green” Renewable Diesel. Unlike biodiesel, which is comprised of methyl esters, Renewable Diesel is made up of saturated alkanes, making it molecularly identical to traditional diesel. This allows Renewable Diesel to be a direct plug-in to increase the renewable make-up of refined products, all while using technologies already familiar to refiners.

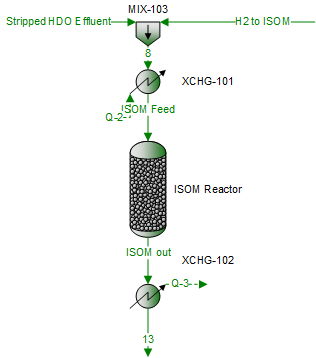

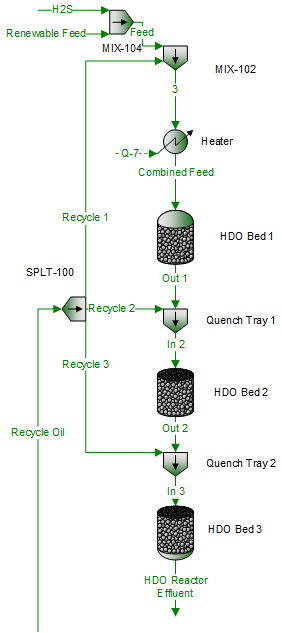

Harness the power of ProMax’s AutoKinetic reactors to rigorously model the saturation, hydrodeoxygenation, and isomerization of a full suite of triglycerides.

From feed pretreatment to products separation, ProMax allows the user to model the entire renewable diesel process!

- Calculate H2 consumption for various vegetable oils

- Balance cetane and pour point with isomerization operations

- Optimize H2 and oil recycle

- Minimize undesired cracking and product losses

- Separate reactor effluent into saleable products

- Discover optimal quench gas rates to improve conversion

- Blend products with petroleum based diesel to confirm product specifications

- Determine how operations affect propane, naphtha, and diesel yields.

- Utilize a full range of fatty acids from Palmitic (16:0) to Linolenic (18:3) as well as their constituent triglycerides

- Add predefined vegetable oils, including soybean, palm, and canola using ProMax Mixed Species

- Calibrate to operations for predictive modeling of the reaction chemistry, including adsorption to the catalyst, hydrogenation, hydrodeoxygenation, cracking, and isomerization.

- Use ProMax’s strength in hydrocarbon modeling to assess product distillation operations