Caustic Systems

Leveraging four decades of electrolytic modeling experience, ProMax® provides extremely accurate and easy-to-use capabilities for fast, robust caustic system modeling. Almost any configuration or system can be modeled, including acid gas removal from ethylene washes,

mercaptans removal from hydrocarbon liquids, selective SO2 scrubbing, and more!

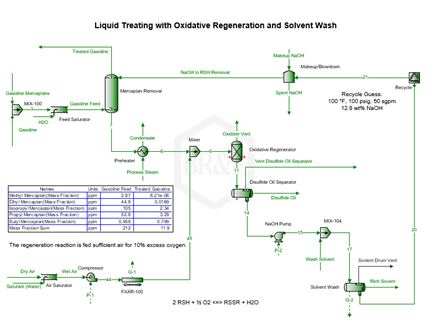

Regenerative Caustic Systems for Mercaptans Removal

- Calculate Mercaptans Absorption from vapor-liquid or liquid-liquid columns

- Perform Oxidative or Thermal Regeneration of the Rich Caustic

- Have confidence in advanced thermodynamics for accurate distribution of mercaptans, disulfide oils, and water in three-phase systems

- Scrub regenerated caustic with hydrocarbon liquid for further disulfide oil removal

- Determine minimum air flow requirements to oxidative regenerator

- Calculate spent caustic rates due to H2S and CO2 ingress into the system

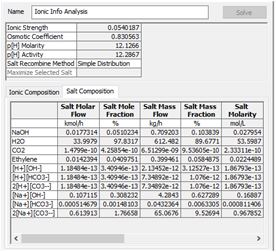

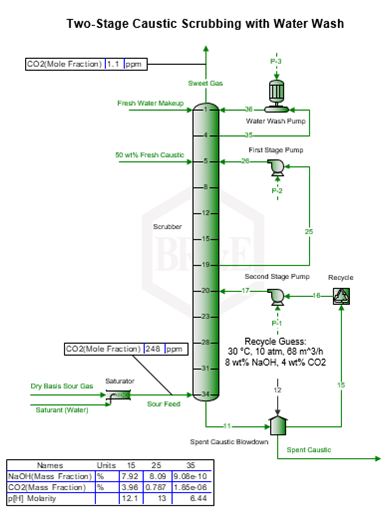

Caustic Scrubbing of Ethylene

- Mass+Heat Transfer Model for High Accuracy

- Easily set pumparound loops for multi-stage designs

- Ionic Info Analysis provides simple tracking of spent vs. free caustic in the solvent loops

- Integrated water wash loop for clean model appearance

- Optimize pumparound rates and caustic addition/removal to minimize costs

- Determine correct number of trays required to meet tight product specification

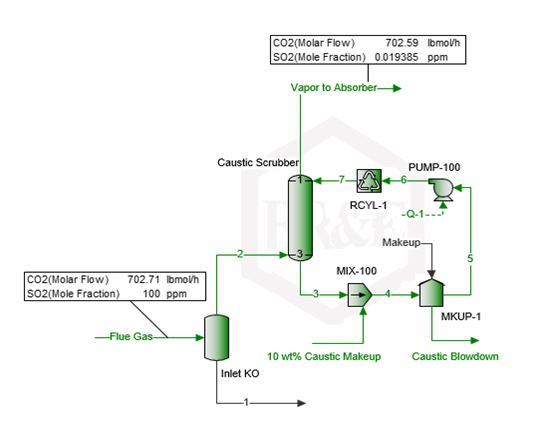

Selective SO2 Scrubbing from Flue Gas

- Mass+Heat Transfer Model for High Accuracy

- Easily set pumparound loop for balanced L/G

- Ionic Info Analysis provides simple tracking of spent vs. free caustic in the solvent loop

- Optimize pumparound rate and caustic addition/removal to minimize costs

- Determine correct number of trays required to meet desired SO2 selectivity

- Estimate cost of flue gas scrubbing to meet MARPOL requirements on use of high sulfur bunker fuel