Control Valves

ProMax includes a wide variety of Control Valve information, to help you size this equipment, or estimate the pressure drop

that results from their utilization. Choosing an appropriate type is crucial for accurate control valve calculation: our library

includes over 450 types of Baumann™ and Fisher™ control valves, each type including identifiers to set the valve nominal size, port

diameter, or maximum travel. If the ProMax Control Valve library does not include the valve you are using, a user-defined valve can

be created by either entering the valve data directly in the table, or modifying our “Control Valve Data.xml” file to add a new valve

type and flow coefficient data.

The Control Valve Analysis calculations are primarily based on the discussion and equations in the Control Valve Handbook. ProMax

Control Valve Analyses include valves for incompressible flow liquid service and compressible flow vapor services, and also correlations

for 2-phase flows based on the Sheldon and Schuder (1965) methodology.

Estimate Current Valve Flow Coefficient, Cv

ProMax allows the user the option to specify the valve opening percentage, or to have this value determined by a specified pressure

drop or downstream pressure. At the stream conditions, ProMax will calculate the current Valve Flow Coefficient, or Cv. This value is

an indicator of a given valve’s flow capacity and is the main parameter used to size control valves. The ANSI-ISA-75.01.01-2002 formulation

of the Flow Coefficient is dependent on the flow regime and choked/non-choked conditions. ProMax will compare the Calculated Cv for your

process conditions, and report if this exceeds the Valve Cv, determined by the flow coefficient database.

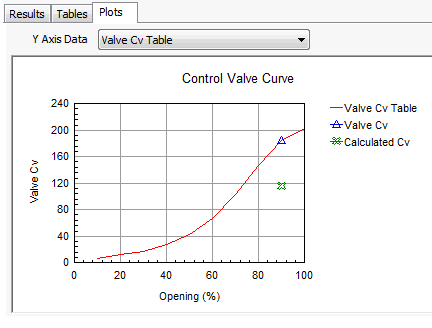

The ProMax Control Valve Analysis results includes tables and plots showing values for the Valve Cv, Choked Pressure Drop, and Choked Mass

Flow for a range of valve openings from 10% to 100%.

Estimate the Flow Resistance, K

After the Calculated Cv has been determined for your control valve, ProMax will also calculate the Valve K, or flow resistance.

This value can be specified directly in a ProMax Pipeline block, overriding the estimated value from the Pipeline library, and allowing a

more accurate simulation tailored to your specific valve selections.

Calculate a Valve Maximum Working Pressure

ProMax can also help you determine a Maximum Working Pressure at the minimum manufacturer quoted valve pressure class for your current

process stream temperature and pressure. This calculation is performed by selecting a Valve Body Material from a simple drop-down list.

Directly Apply Calculated Pressure Drop to Simulations

A JT Valve block in ProMax can utilize the Control Valve calculations as a pressure drop method, allowing your simulation to automatically

account for the pressure drops associated with your control valves. The prediction of pressure drop in the Valve block using the calculations

of the Control Valve Handbook will seamlessly update as flow rates change at various scenarios run in your model, and will issue an error

if the pressure drop exceeds the available pressure at any point. If choked conditions are estimated, or if the calculated mass flow through

the valve is less than the stream flow, the block is labeled as approximate, helping you to diagnose potential issues.