Piping and Networks

Pipeline Block

The ProMax Pipeline block is a flexible and powerful tool for estimating the flow characteristics and pressure change associated with a single pipeline,

a gathering system, a well bore, or even a flare network. Our rigorous pipeline block can help you determine the necessary compression for a booster station,

the MeOH flow rate required to prevent solids formation, the liquid holdup you can expect in a line, or any of hundreds of other scenarios. Backed by the

well-tested ProMax Thermodynamic Property Packages, and including properties from hundreds of materials to choose from, including a broad selection of irons,

steels, alloys, and thermoplastics, ProMax offers options for modeling most processes.

In the ProMax Pipeline, pipe segments of different inclination angles or sizes can be combined with fittings, reducers, or isentropic nozzles within a single block.

The ProMax Pipeline block includes a library of over 100 common fitting types, and pressure drop estimations to assist you in setting up your pipe. If ProMax does

not include the fitting type or pressure drop properties for a fitting type that you would like to use, user-defined fittings are available for you to specify. Each

segment in the ProMax Pipeline can independently have a user-set number of increments to allow phase property calculations performed with a chosen accuracy. Freeze

calculations can be performed at each increment permitting a user to find where in a pipeline hydrates, ice, or dry ice may first form under varying conditions. If

sonic conditions are predicted by ProMax, warnings are issued.

Buried Pipe – The ProMax Pipeline block includes a collection of ground types and estimated thermal conductivities for each, allowing an

estimated heat transfer coefficient to be calculated for losses to the environment directly by ProMax. If ProMax does not include the ground type or heat

transfer properties for a ground type that you would like to use, user-defined ground types are available as well.

Buried Wellbore – Since the heat transfer to the surrounding earth is a transient process with a wellbore, estimating the correct value

at various wellbore flowing times is essential. Coupling our pipeline block and the ProMax Scenario Tool® can assist you in finding how much energy

transferred with the surroundings as this changes, or if the well has already reached a steady-state temperature distribution.

Submerged – If the pipeline is submerged in water, the outside fluid velocity can be specified for ProMax to estimate the heat transfer;

if the fluid is essentially still, ProMax will estimate the buoyant effects due to free convection.

Above Ground – The outside air velocity can be specified for ProMax to estimate the heat transfer to the environment, similar to how a

submerged pipe transfers energy with the surrounding water. If the air is essentially still, ProMax can calculate the buoyant effects due to free convection.

Insulation options are available, including a collection of common types and estimated thermal conductivities for the pipelines; the user may set multiple layers,

both the type and thickness of each layer.

If the ProMax library of insulations does not include the type or heat transfer properties for what you would like to use, user-defined insulation types are available

as well. If you believe that the insulation is efficient enough to provide adiabatic conditions for the pipeline flow, you can easily simplify the model and ignore

heat transfer to the environment.

ProMax offers rigorous and specialized calculations for the fluid(s) flowing through the pipeline, allowing our pipelines the same quality of results expected from

ProMax. Special thermodynamic property correlations are available for both brines and emulsions in the simulation. Multi-phase flow correlations are available for a

variety of conditions, including some designed exclusively for upward flow, some for horizontal flow, and some for any angle of flow; choices available include:

Aziz-Govier-Fogarasi, Beggs and Brill, Dukler et all, Duns and Ros, Lockhard-Martinelli, Lockhard-Martinelli Modified, Mandhane-Grogory-Azia, and Orkiszewski. By default,

ProMax utilizes correlations that account for calculated kinetic energy effects of flow – when modeling a gas phase with a significant change in velocity, these kinetic

effects can be significant.

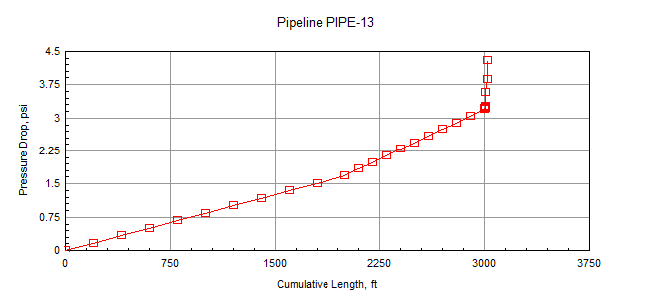

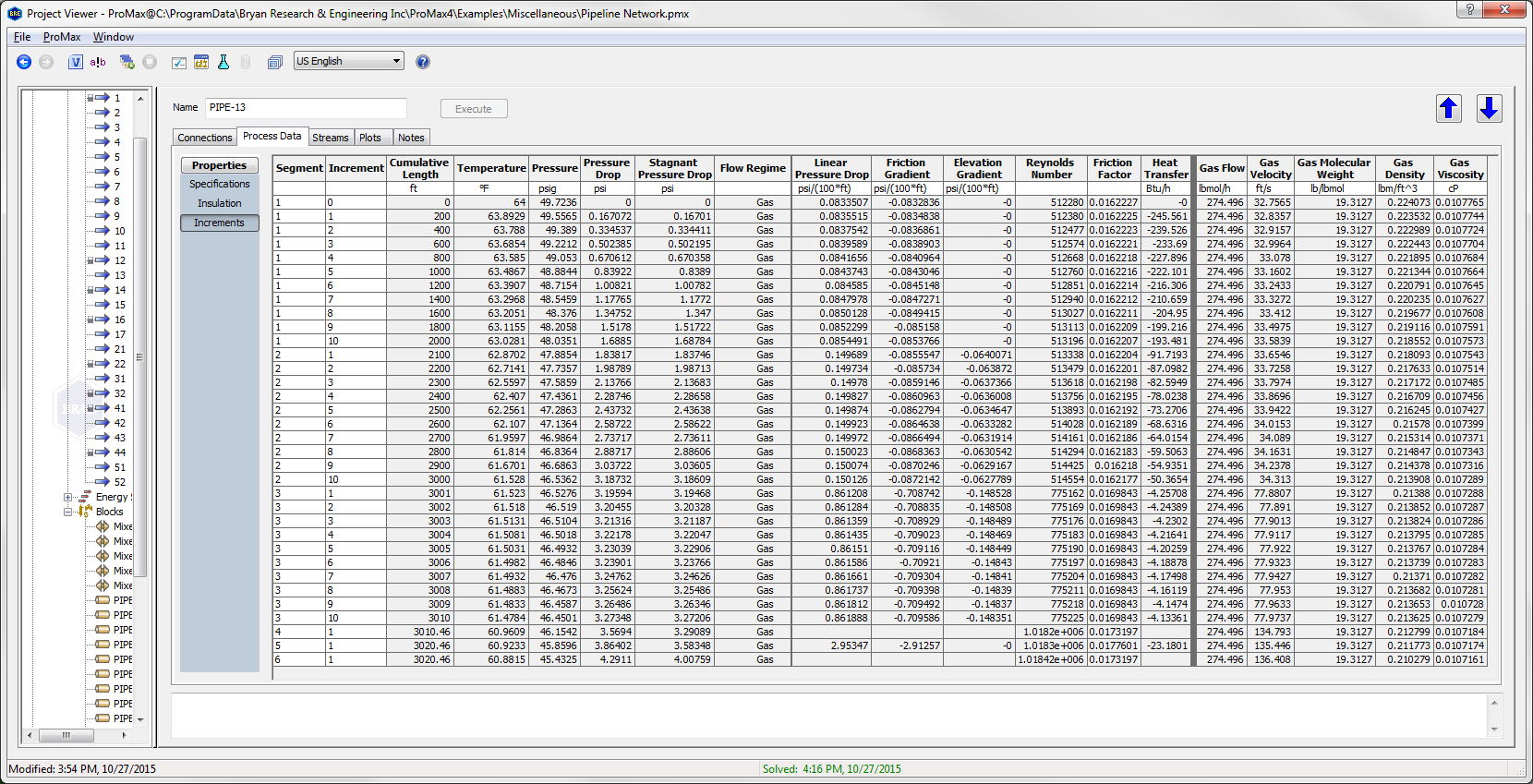

The results generated by ProMax are available in both an easy to read table, and automatically generated plots. The values and plots can be copied from ProMax into Excel,

Word, or PowerPoint providing a ready source for presentations or further investigations. If you have any questions while working with the pipeline block, the ProMax Help

contains in-depth discussions to assist in correctly modeling different systems, and the ProMax Support team is available to discuss any questions with our clients.

Line Sizing Analysis

If your goal is to estimate the size of lines required throughout a plant, without the detailed flow characteristics, ProMax additionally offers a Line Sizing analysis for any process stream.

- Quickly calculate either the minimum diameter that meets the pressure drop specification, or the pressure drop for a fixed pipe diameter.

- Estimate sizing for single phase and multi-phase flow.

- Calculate the maximum allowable working pressure (MAWP) in the pipe based on a selection of Pressure Vessel Codes, including ASME.

- Estimate the erosional velocity using API RP 14E.

- Limit velocity in the pipeline, allowing ProMax to suggest a larger line size based on velocity constraints, if necessary.