Carbon Capture and Sequestration (CCS)

Carbon capture and sequestration involves capturing CO2 emissions generated from industrial processes, allowing operators to reduce GHG emissions while continuing to offer reliable, cost-effective energy across the globe.

Rely on our experience and expertise, in conjunction with our precise, robust software to deliver optimal evaluations and design solutions!

Modeling considerations

- Mass & Heat Transfer-based distillation columns (Trayed, Random, or Structured Packing)

- Lean/Rich Loading and Approach Calculations

- Comprehensive Absorber Temperature Profiles

Property Packages for CO2

- Span-Wagner, GERG-2008, PR, SRK, and Electrolytic ELR

CO2 Solvents Available in ProMax

- Traditional Amines: MEA, DGA, DEA, MDEA, TEA, DIPA, AMP

- Other Amines: PZ, AEP, MMEA, MOR, DEEA, DMEA, MIPA, 1-MPZ, EHEP, HEM, DETA, EDA, HMDA, TEDA, HEP

- Amino Acids: Glycine and Sarcosine

- Proprietary Solvents

- Huntsman JEFFTREAT®

- Dow UCARSOL™

- Eastman AdapT

- Physical Sweetening Solvents like Methanol, DEPG, and Propylene Carbonate

- Hot Potassium Carbonate

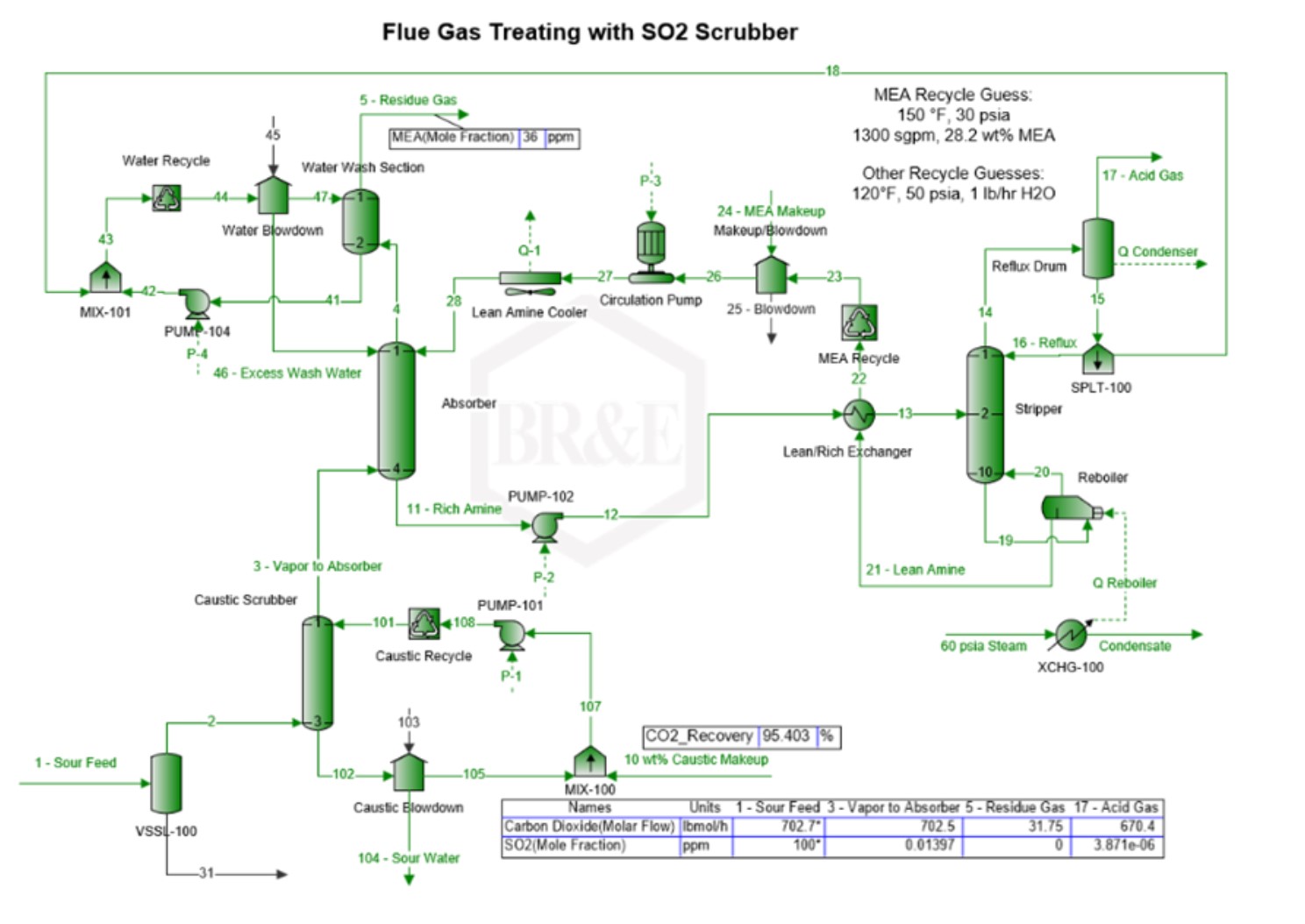

Flue Gas Capture

Whether from thermal power generation, cement plants, or other sources, ProMax provides accurate,

reliable simulation of carbon capture units from flue gas using a variety of popular and emerging

solvents. ProMax’s versatile simulation capabilities facilitate integration of these capture units with

other facilities, such as combined-cycle power plants, enabling holistic process optimization.

- Rigorous electrolytic thermodynamics

- Rate-based modeling

- Column hydraulic modeling

- KPI tracking throughout CCS unit

- Upstream scrubbing of SOx

- Energy Intensity Calculations

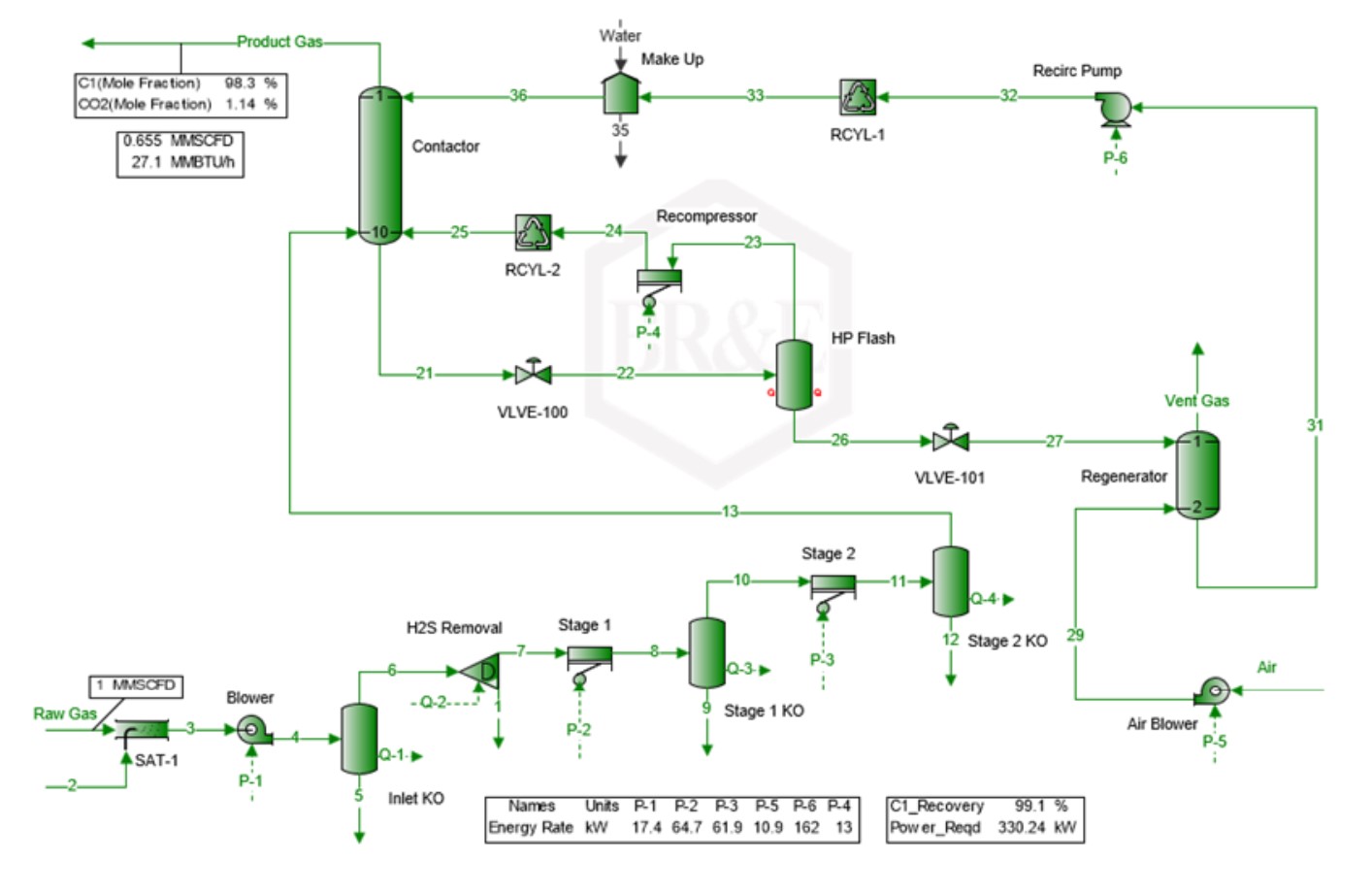

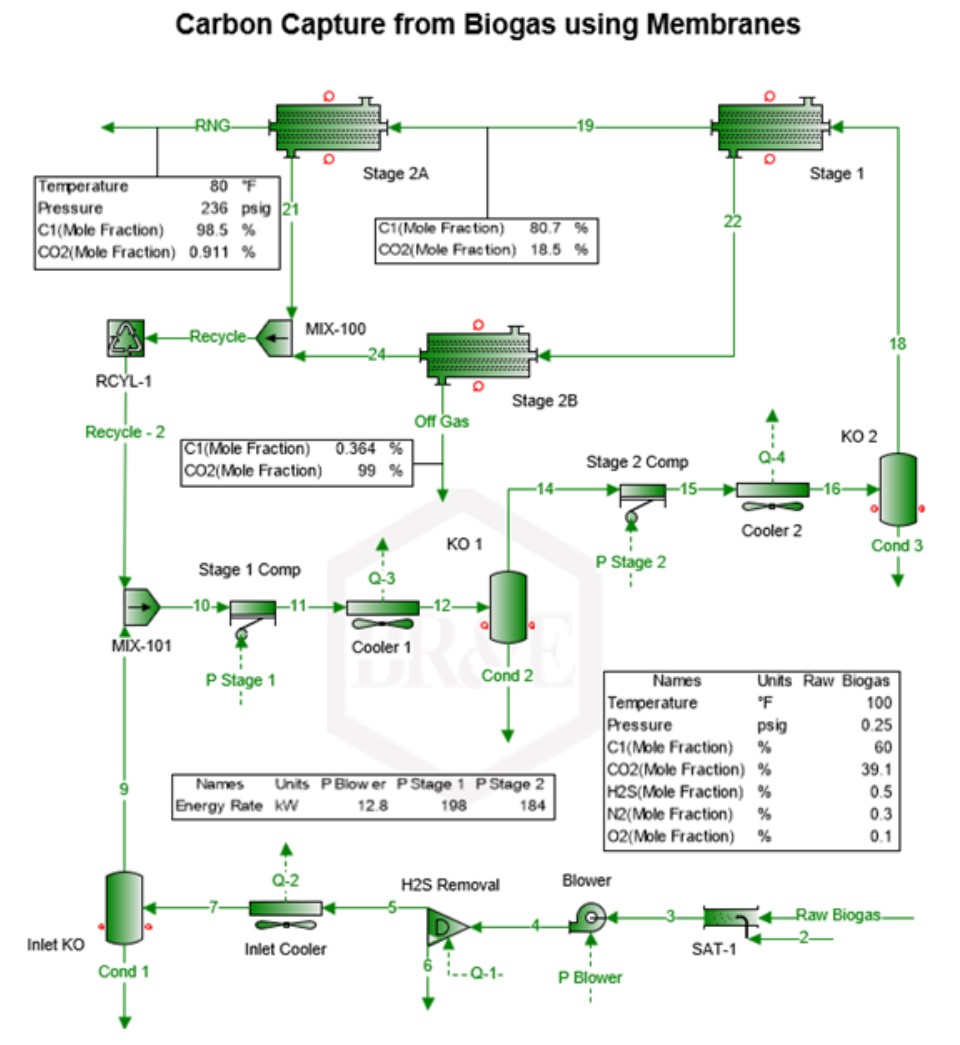

- Membrane separation

- User defined permeability for Cellulose Acetate used for separation treating

- RNG treating

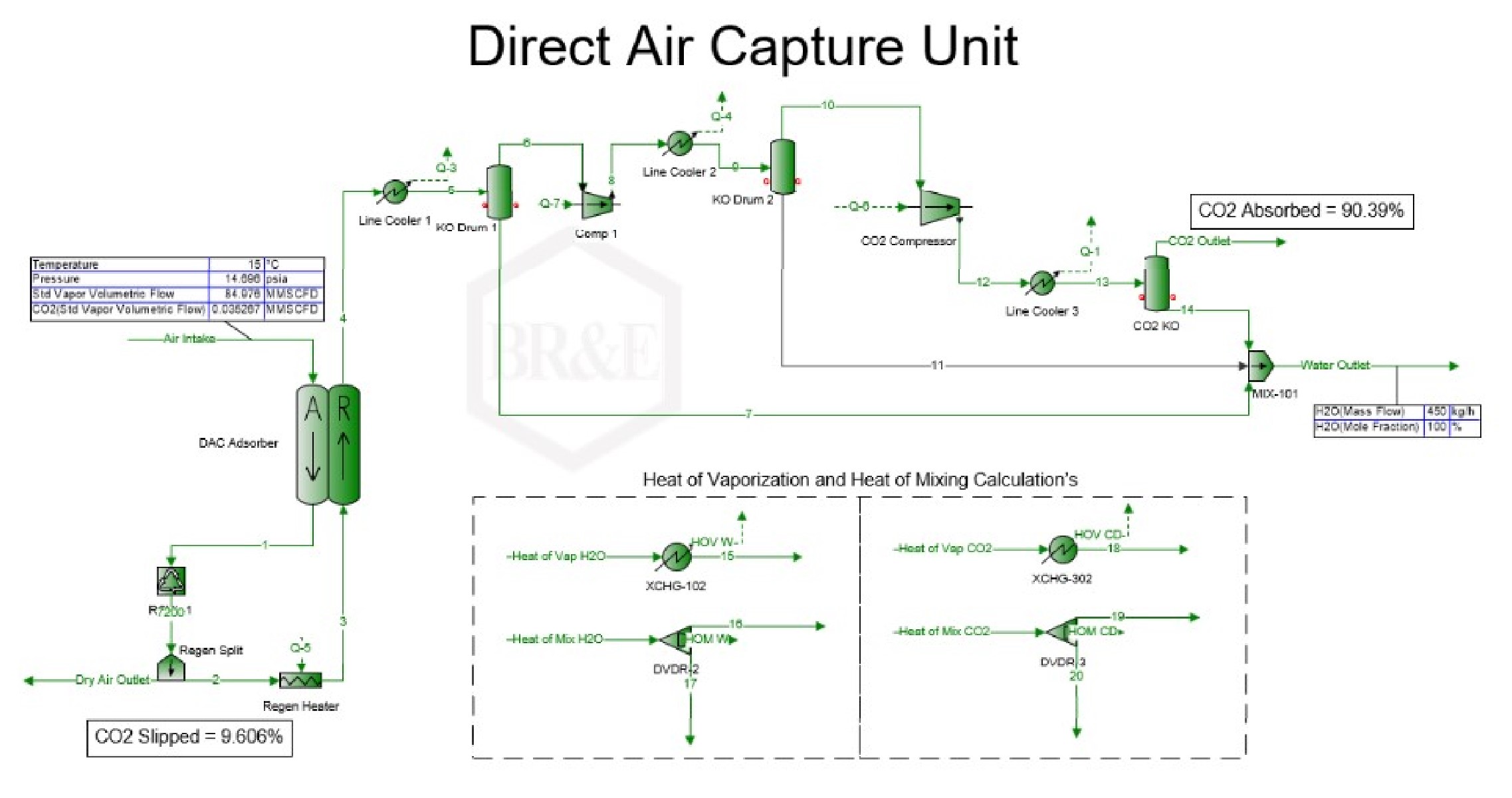

Direct Air Capture

Direct Air Capture (DAC) is a technology engineered to extract CO2 directly from the atmosphere. ProMax plays a pivotal role in modeling DAC capabilities by offering a robust platform for

comprehensive analysis and process optimization.

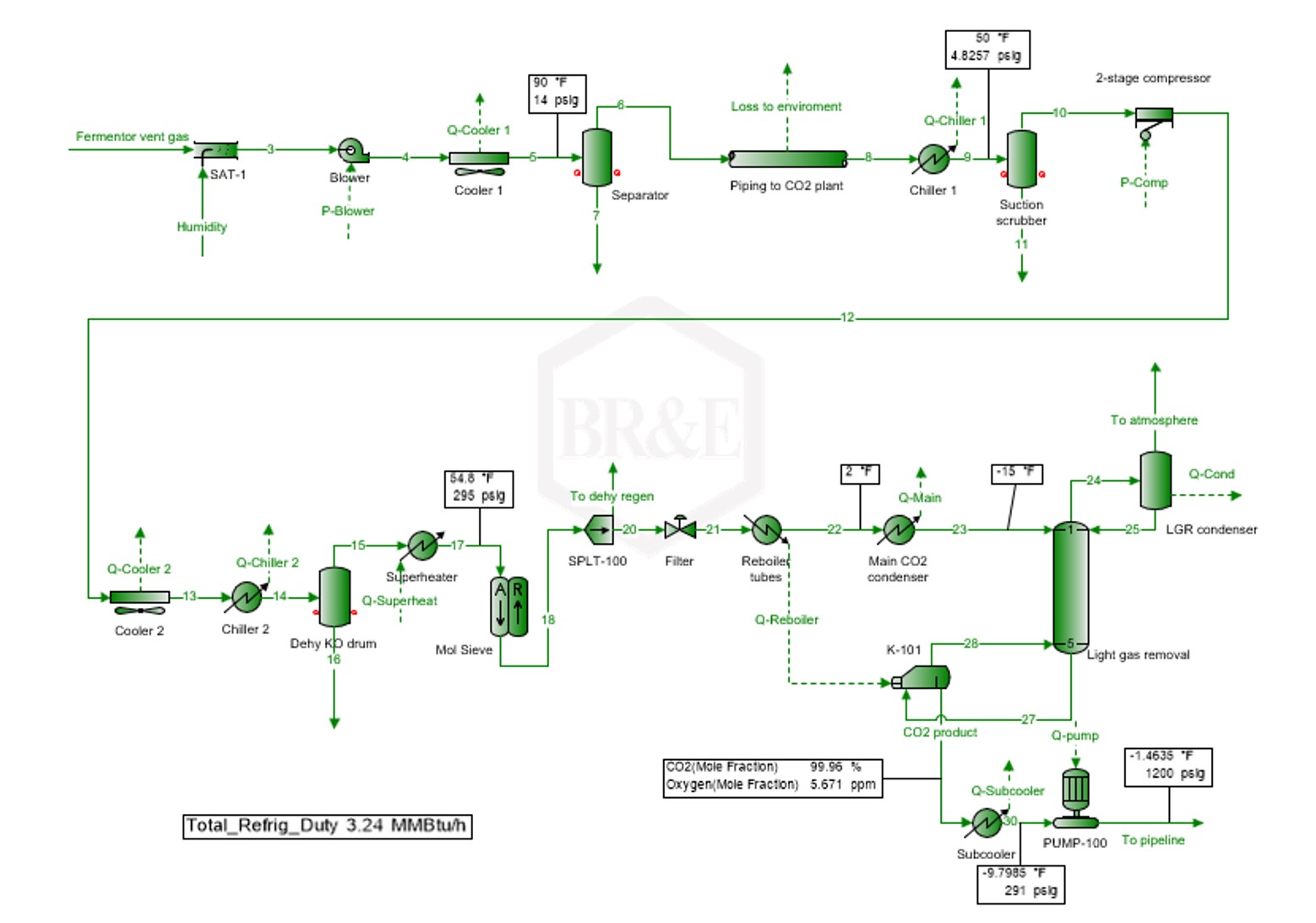

Ethanol Plant Capture

Ethanol plant capture involves capturing and managing CO2 emissions generated during ethanol

production, aiming to minimize their environmental footprint. Utilize ProMax to evaluate alternatives

for vent gas treatment including:

- Compression

- Dehydration

- Liquefaction

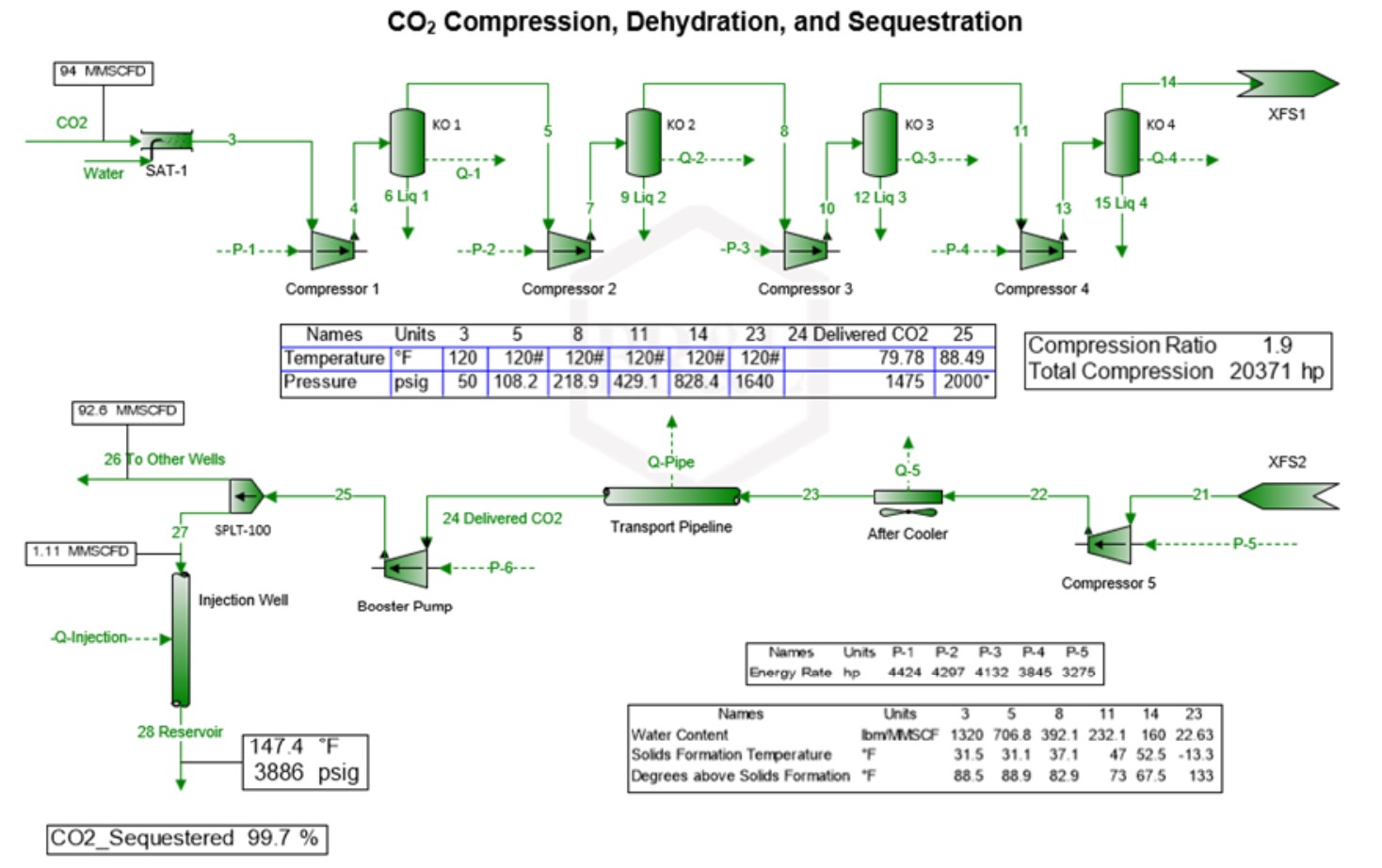

CO2 Compression, Dehydration, Transportation, and Injection

Once captured, CO2 requires compression and transportation for final utilization or sequestration. With

ProMax, you can simulate the complex phase equilibria between CO2 and H2O mixtures at near critical

and supercritical conditions. This is crucial for evaluating captured CO2 compression, dehydration,

transport, and downhole injection. ProMax accurately predicts:

- Water content

- Density

- Glycol dehydration thermodynamics

- Solids formation temperatures (Hydrates, Water Ice, and Dry Ice)

- Pipelines

With nearly five decades of dedicated application, ProMax assures dependable accuracy in assessing power requirements, phase equilibria, and fluid properties for pure and contaminated CO2!

Watch our Webinar to Learn More about our Carbon Capture Capabilities here