Blue Hydrogen

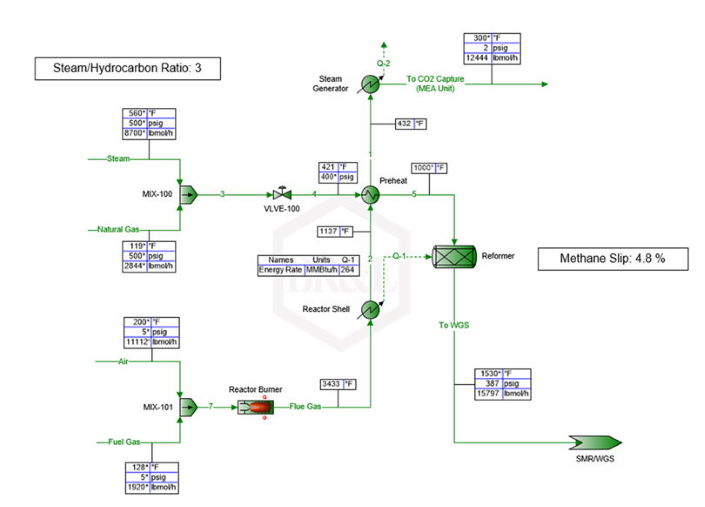

ProMax 6.0 is a great choice for simulating the various Blue Hydrogen production options which often include Carbon Capture, Utilization, and Storage (CCUS).

Relevant reacting systems below can be modeled using ProMax:

- Steam Methane Reforming with Flue Gas CO2 Capture

- Autothermal Reforming

- Pre-reforming

- Tri-reforming

- Partial Oxidation

- Water Gas Shift

- Gibbs Reactor with active component selection and option of User-Defined Linear Constraints on product component compositions

- Equilibrium Reactor with Approach Temperature Constraints

- Plug Flow with Kinetic Rate configuration including Adsorption Terms.

ProMax is the leading simulator for pre- or post-combustion capture process to remove CO2 from gas streams:

- Over 40 years of perfecting

- Rigorous Electrolytic Thermodynamics with Ionic Stream and Stage Phase analyses

- Generic Amines and Proprietary Sweetening Solvents from Huntsman, Dow, and Evonik

- Mixed Amines

- Physical Sweetening Solvents such as Methanol, Coastal AGR, and Propylene Carbonate

- Potassium Carbonate

- Ideal Stage or Heat & Mass-Transfer Based Distillation Columns (Trayed, Random, or Structured Packing)

- Regenerator Water Purge for High Temperature Feed Gases

- Loading and Lean/Rich Approach Calculations

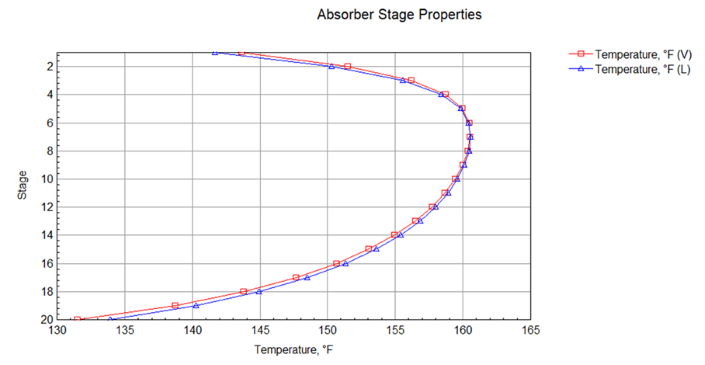

- Absorber Temperature Profiles

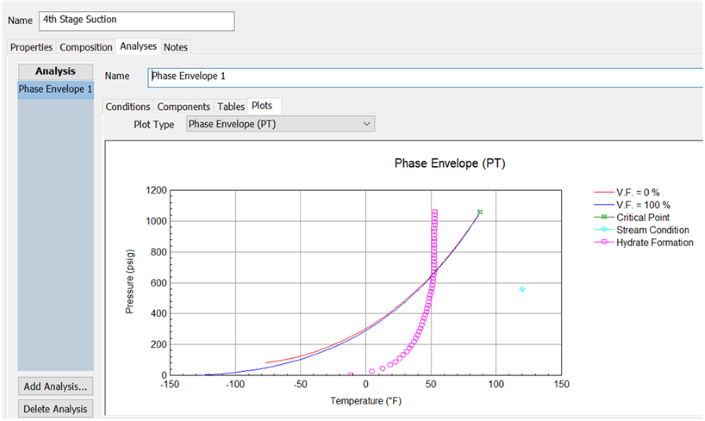

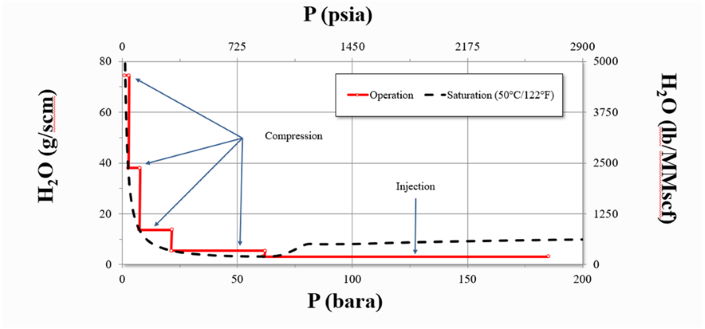

ProMax developers have mastered the complex phase equilibria between CO2 and H2O mixtures at near critical and supercritical conditions. This becomes very important when evaluating captured CO2 compression, dehydration, transport, and downhole injection. To do these accurately requires accurate prediction of:

- Acid gas water content

- Acid gas density

- Glycol Dehydration thermodynamics

- Solids formation temperatures (Hydrates, Water Ice, and Dry Ice)

- Pipelines

Other simulation tools to improve users’ experience when evaluating these processes are:

- Excel Integration and Scenario Tool for performing multiple case studies

- Project and Flowsheet-Level Recovery Calculator

- Analyses for Calculating Special Properties of Streams and Stage Phases (Combustion, Phase Envelope, Solids Formation, Line Sizing, etc)

- Multiple Flowsheets likely having different thermodynamic packages integrated into a single simulation project

- Equipment rating and sizing utilities (Distillation Column, Heat Exchanger, Separator, Valve, Pipeline, Pump, Compressor, Expander)

- Excellent Units Conversion, Property Display, and Flowsheet Annotation features