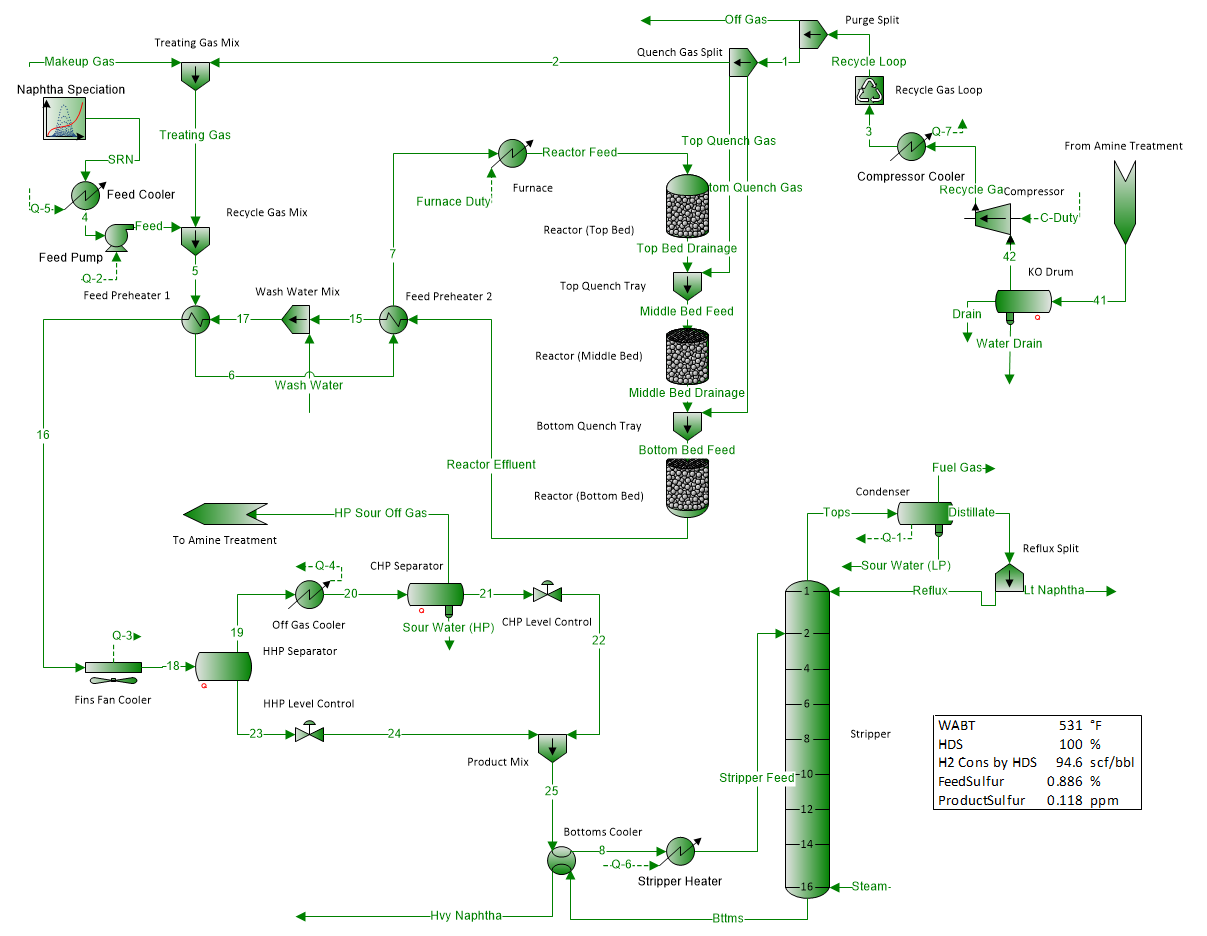

AutoKinetic® Reactors

ProMax AutoKinetic reactors provide a suite of rigorous reactor models to simulate petroleum refining processes.

Among other benefits, these models can accurately predict reactor operations to achieve optimized operating targets and provide fundamental details on

reactor performance for design and debottlenecking.

-

Computer-generated reaction sets from chemistry fundamentals

-

Customizable reaction sets based on user’s selection of species in simulation environment

-

Simplified workflow that removes the burden of introducing reactions, rate expressions or kinetic parameters from users

-

Open access to model kinetic parameters

-

Easy-to-use Oil Speciation capabilities to convert Assay data into a species mixture

-

Intuitive model calibration using user proprietary data

-

Flexible multi-bed reactor configuration with seamless integration of heat/quench operations

-

Powerful graphical tools for performance analysis

-

CAPE-OPEN compliant solution

Kinetic Models

ProMax AutoKinetic reactors include a series of scalable kinetic models specifically designed to simulate Hydroprocessing operations.

- Catalytic Reforming

- Isomerization

- Hydrodesulfurization

- Custom Metal/Acid Catalyst Kinetics

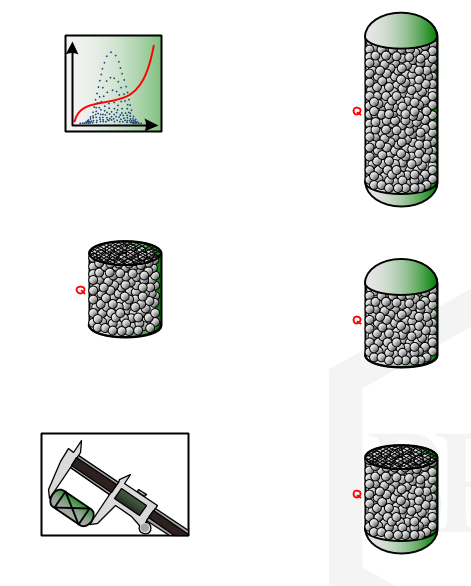

Catalytic Fixed Beds

Model catalytic fixed beds as found in process units across refineries. Predict hydraulic losses in polydisperse particle beds (grading).

Unfold the impact of particle shape, size and density on packing.

Kinetic Calibration Tool

A powerful model tune-up tool is available from the ProMax flowsheeting environment. This tool provides an easy-to-use graphical interface to calibrate kinetic parameters from plant data.