Sulfur Recovery and Tail Gas Cleanup (TGCU)

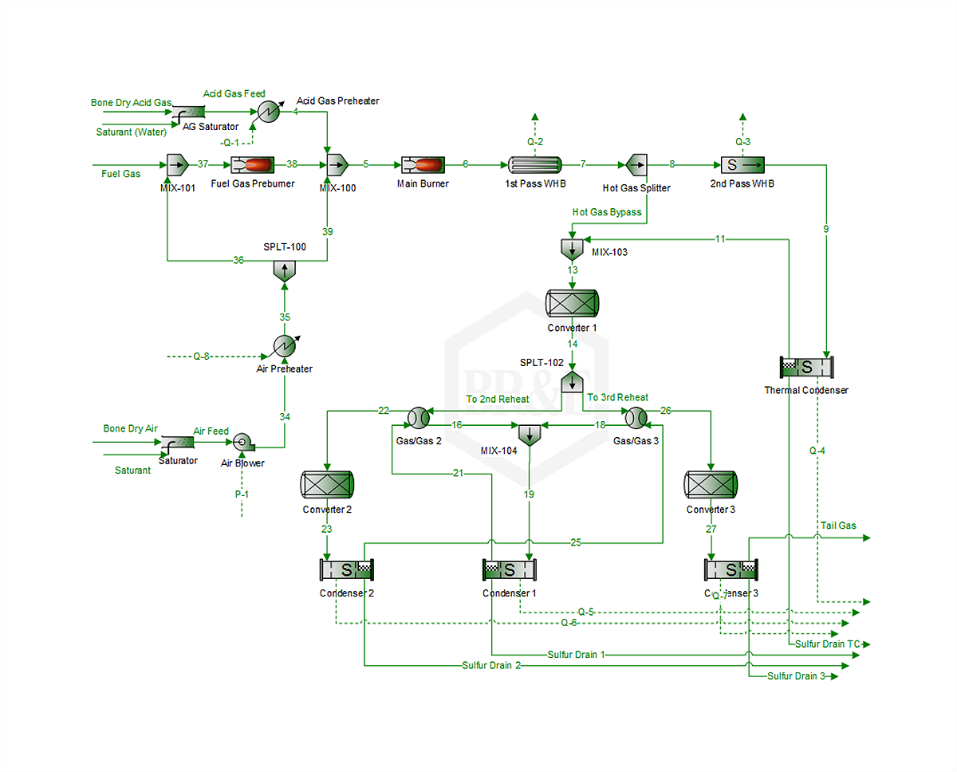

ProMax contains a complete suite of reactor models facilitating an easy-to-set-up, yet accurate model of sulfur recovery unit operations.

A theoretical approach with empirical modifications allows the user to model real world behavior, whether for the Claus Process itself or a variety

of other Claus/Tail Gas technologies.

- Model specific Claus configurations such as acid gas bypass, hot gas bypass, enhanced oxygen, catalytic burners, and more.

- Selectox/Recycle Selectox®

- COPE™

- Ultra®

- Sulfreen®

- SCOT®

- SUPERCLAUS®

- MODOP®

- CBA®

- EUROCLAUS®

Benefits

- Directly link the amine, sulfur and tailgas units all in one project

- Optimize plant performance through custom solver routines

- Automatically determine overall plant sulfur recovery

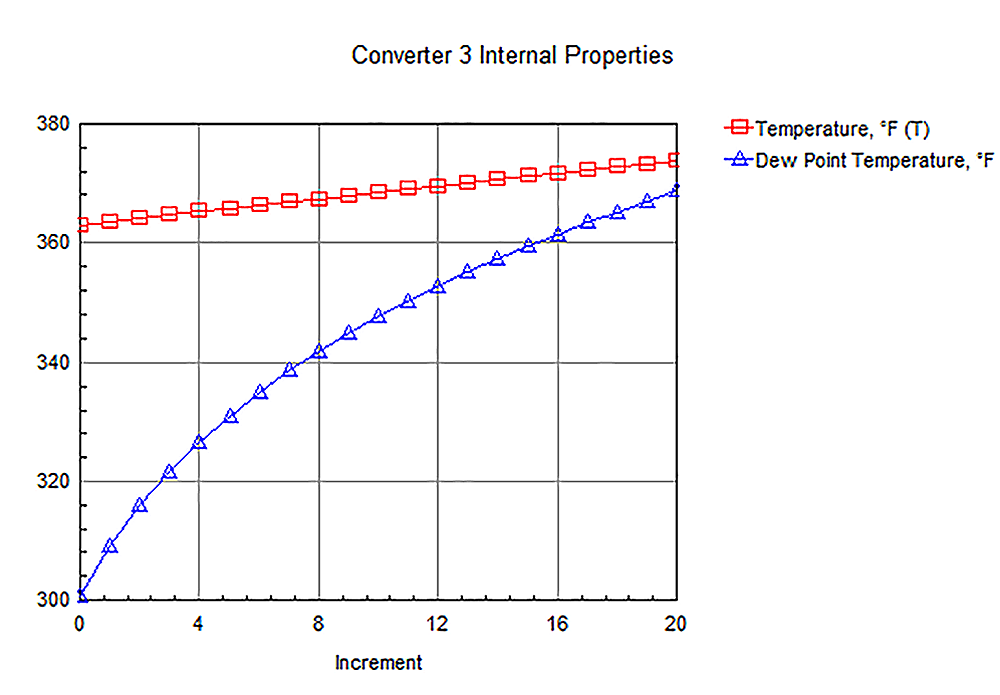

- Easily determine the sulfur dewpoint at any point in the system

- Calculate steam generation and consumption quantities

- Integrate the complete steam system into the simulation

ProMax Sulfur Plant Reactor Applications

ProMax uses predefined Gibbs reaction sets to make it very easy for the user to model the plant. Simply select the reactor type

from a drop down list and the appropriate components

for that reaction will automatically be selected for inclusion across the reactor. Some of the predefined reaction sets are listed below.

Acid Gas Burner

This Gibbs Set has default settings used to model

the burner at the inlet of a

Claus sulfur recovery unit. All Components are

included by default. Default Constraints

are selected to predict CS2 and COS

formation in the burner.

Burner

This can be used to model any type of reactor in a sulfur recovery unit. No constraints are set by default, and all components are

Gibbs Reactive (e.g. all components are included in the reaction). This model could be used to model an incinerator or Reducing Gas Generator (RGG).

Claus Bed

This Gibbs Set has default settings used to model standard Claus beds. The Bypass Fraction parameter is used to effectively set an approach

to equilibrium conversion when matching plant data. This type Gibbs Set is not intended to model the first Claus bed since the first Claus

bed temperature and catalyst type should be such that COS and CS2 are destroyed.

Sulfur Direct Oxidation

This Gibbs set has default settings intended to model a Selectox type reactor or catalyst burner which can replace the conventional

burner for cases with very low H2S. This type reactor is also sometimes used for tail gas applications.

Sulfur Partial Oxidation

This Gibbs Set has default settings intended to model the SUPERCLAUS type direct oxidation bed at the end of the Claus unit.

Hydrolyzing Claus Bed

The default settings for this Gibbs set are intended to model the

first Claus bed where the temperature and catalyst type are typically such that COS and CS2 are destroyed.

Sub-Dewpoint Claus Bed

This type Claus bed operates below the sulfur dew point. This Gibbs Set has default settings used to model the 2nd and subsequent Claus beds.

Sulfur Condenser

This type of reactor condenses sulfur species from the vapor to produce a liquid sulfur product. Available sulfur allotropes range from S1 to S8.

Sulfur Hydrogenation

The default settings for this Gibbs Set are intended to model the Tail Gas Cleanup Unit (TGCU) Hydrogenation reactor in which all sulfur species

are converted to H2S. The TGCU Hydrogenation reactor is normally used in conjunction with a Reducing Gas Generator (RGG) Reactor for the tail gas.

Hydrocarbons and ammonia are the only non-reactive components by default.

Sulfur Redistribution

The default settings for this Gibbs Set are used to model the 2nd pass of the waste heat boiler from about 1200 °F to 600 °F (648.9 °C to 315.6 °C)

where the redistribution of sulfur species is the primary reaction.

Sulfur Thermal Reaction Zone

The default settings for this Gibbs Set are intended to model the 1st pass of the waste heat boiler from the burner flame temperature down to

about 1200 °F (648.9 °C).

COS and CS2 Formation and Destruction

COS and CS2 are formed in the acid gas burner,

and are partially destroyed in the first Claus bed

provided the appropriate catalyst is present and the

temperature is sufficiently high.

Equilibrium models do not adequately predict the

formation of COS and/or CS2 in the burner

as observed concentrations can be significantly

higher than equilibrium predictions. A number of

semi-empirical correlations have been developed to

more accurately predict COS and CS2

formation in the burner:

Fischer 1974 - This correlation predicts the

concentration of COS, CS2 out of

the burner.

Luinstra d'Haene 1989 - This correlation

predicts the concentration of CS2

out of the burner and requires a residence time

specification.

NSERC 1993 - This correlation predicts the

concentration of COS, CS2 out of the

burner.

NSERC 2002 - This correlation predicts the

concentration of CS2.