Relief Systems

Relief Valve Block

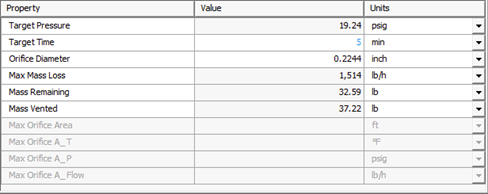

Starting in ProMax 6.0 there is a new relief valve block that will allow you to compare a variety of different relief scenarios in one location.

The new relief valve block has a number of new features as well including:

- Both rating and sizing of a relief valve

- Allowing the inclusion of both inlet and outlet piping

- Both the Omega method and the Direct Integration method for multiphase systems

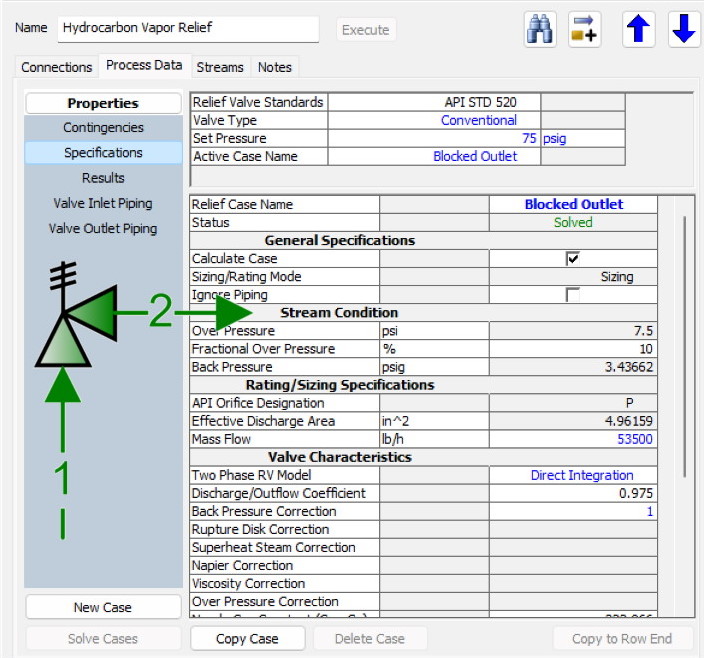

- Multiple Scenario comparison within one block along with a results summary for easy comparisons

Let ProMax help you accurately size your relief valves, allowing you to protect equipment from excessive overpressure, while avoiding issues with

excessive flow rates, including: possible valve damage, impaired performance, undersized discharge piping and effluent handling systems, and higher costs.

Many scenarios can result in an increased vessel pressure, including run-away reactions, loss of cooling, thermal expansion of liquids, or an external fire.

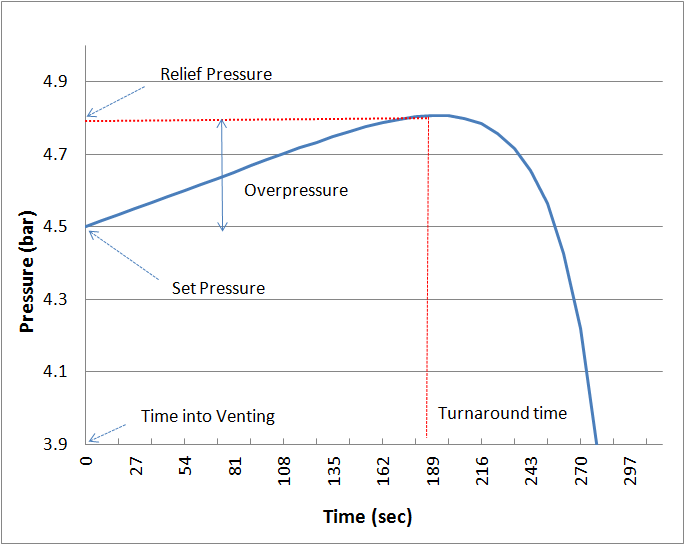

In any of these scenarios, the pressure will increase until a predetermined relief pressure is reached, at which point the relief pressure valve will be open, decreasing the pressure after the turnaround time.

Once the scenario is identified, an appropriate relief type must be selected, as sizing depends on the type of relief device selected. ProMax supports sizing the following:

- Conventional (spring-loaded)

- Conventional + Rupture Disk

- Balanced Bellows

- Balanced Bellows + Rupture Disk

- Pilot Operated

- Pilot Operated + Rupture Disk

- Rupture Disk Only

ProMax provides for reliable and proper sizing of a safety relief valve by giving you:

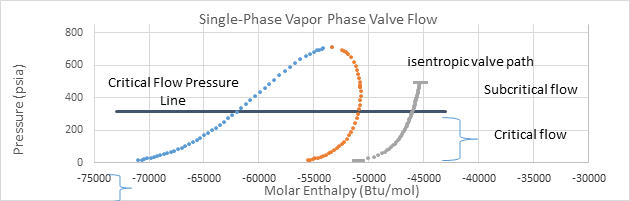

- Rigorous calculations of upstream and downstream fluid properties, utilizing our well-tested ProMax Thermodynamic Property Packages

- Reliable heat and material balances across the system, providing a basis for the accurate prediction of the mass flux through the valve for many different flow regimes

- Estimated discharge coefficients, if you are not provided with a value from a valve vendor and you are uncertain of the non-ideal behavior of your selected valve

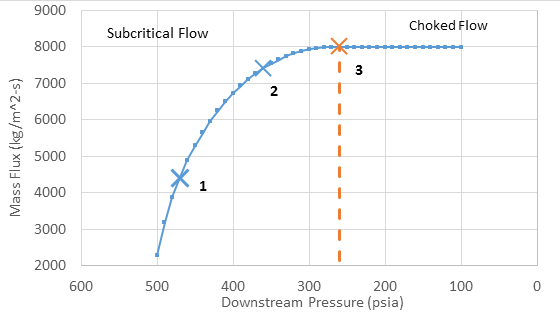

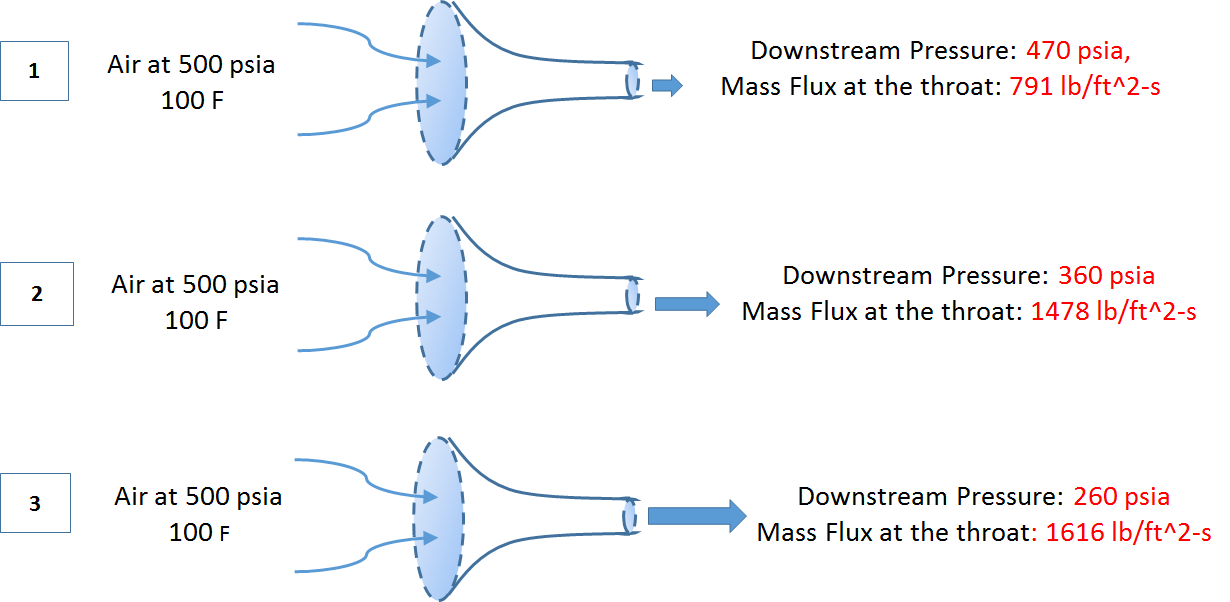

- Dependable predictions of both subcritical flow and choked flow, automatically calculated depending on your fluid conditions and valve specifications

Single and Two-phase flows are supported

Both single and two-phase flows are frequently encountered in various relief scenarios. Due to the large number of variables associated with the fluid properties,

distribution of fluid phases, interaction, and transformation of the phases, sizing a two-phase

relief scenario is considerably more complex than single-phase. A tool that can accurate handle these variables is important. ProMax supports:

- Single-phase liquid flow

- Single-phase vapor

- Flashing two-phase flow

- Non-Flashing-Frozen two-phase flow

- Flashing Two Phase flow with the Effect of Non-Condensable Gases

Relief Valve Standards

There are many different standards for Relief Valve Sizing, each applying different assumptions, thus giving different results. ProMax currently supports six different sets of Relief Valve Sizing Standards:

- ASME API RP520 (7th edition, January 2000) – USA

- EN ISO 4126 – Europe

- AD Merkblatt A2 – Germany

- DIN 3320 – Germany

- TRD 421 – Germany

- BS 6759 - United Kingdom

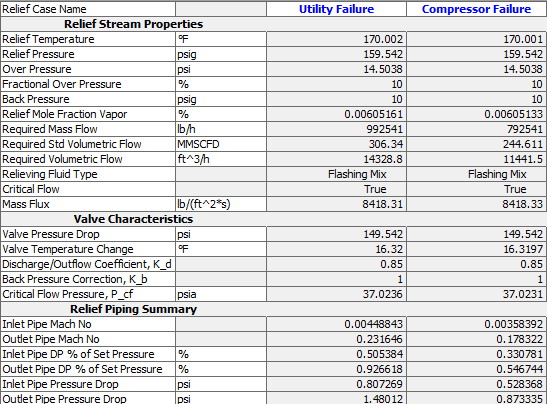

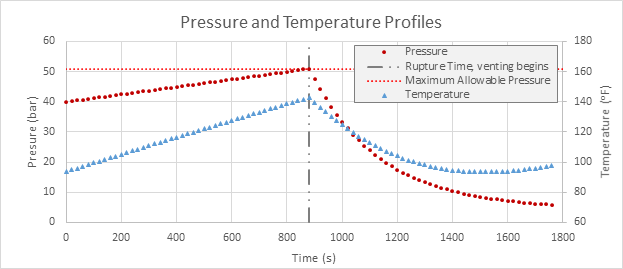

Depressurization

There are many scenarios that can lead to a dangerous increase in pressure of a vessel: valve failures, utility failures, cooling water problems,

broken fans, electric failures, reflux failures, abnormal heat input from boilers, process control failure on reactors or cryogenic fluids,

and many others. Often, the material in the vessel has a wide range of boiling points, or a liquid phase only covers a portion of the vessel.

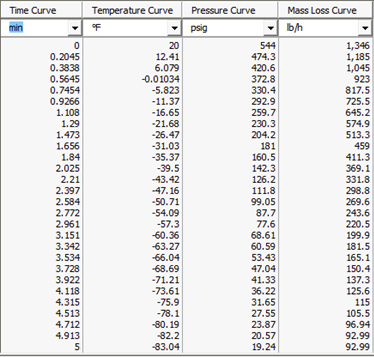

The ProMax Depressurization Tool, available in the ProMax® Property Stencils for all clients, provides a method to study scenarios where changes

over time significantly affect the relief requirements.

The ProMax Depressurization Tool will help you quickly:

- Determine a required orifice diameter

- Estimate the time required to reach a target pressure

- Estimate the pressure after a set period of time

- Calculate the relief conditions and area required for pressure relief over a specified period of time

- Calculate the relief conditions and area required to maintain a maximum temperature

This tool applies to streams, separators, pipelines, and columns in your ProMax project, allowing you flexibility to model what is needed. ProMax

will estimate the vessel volume for most cases, can estimate a fire heat input based on API 521 methodology, and supplies typical default values

for many parameters, helping you quickly get to the results you need.

Once you have obtained your results, you can easily copy the information from the tables into Excel for further evaluation or plotting.