Heat Exchangers

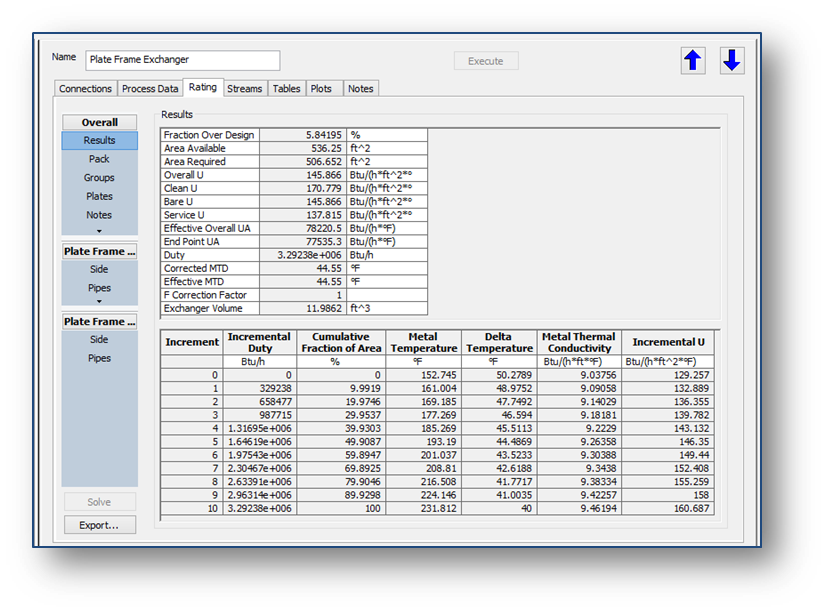

The Heat Exchanger Rating package included in ProMax can help you design new processes, track down bottlenecks, find process inefficiencies,

and decide whether to repurpose existing equipment. Simulation results and user-supplied information can be incorporated

into design calculations for analyzing a variety of heat exchangers, including:

- Shell & Tube

- Plate-Frame

- Fin-Fan

- Double-Pipe

- Compact, including multi-sided Brazed Aluminum

Design and Size New Exchangers

Combining the flexibility of the ProMax Heat Exchanger Rating package with ProMax Simple Solvers and the ProMax Scenario Tool® gives you the power

to design the exchanger you need for your service. Adjust heat exchanger parameters until the area available meets the design and overdesign requirements

for your process. ProMax can simulate plugging tubes to model cases of minor failures, or purposely limiting the heat exchange area. Find anticipated

pressure drops through the exchangers, and any inlet or outlet piping: excessive loss of pressure through associated equipment can mean big money. Let

ProMax help avoid the unexpected by accurate predictions through multiple cases, easily.

Generate a TEMA Specification Sheet directly from ProMax when finished with your design work. This summary of information is a simple way to double-check

vendor supplied information, or provide clients with pertinent details. If licensed to use the HTRI Xchanger Suite® software, ProMax Heat Exchanger information

can be imported, providing additional options and flexibility.

Heat exchanger design requires more than information on simple geometry; a strong thermodynamic property package is required as well. ProMax includes dozens

of pre-defined property packages with unrivaled accuracy across a wide range of processes and process conditions – from cryogenic cold-box or LNG liquefaction,

to hot oil heaters, and everything in between. ProMax includes detailed information on over 90 heat transfer fluids, making accurate design of hot oil heaters as

simple as possible. Solubility information on hydrocarbons and water is unsurpassed, providing the highly accurate fluid properties required for reliable results.

Find Process Inefficiencies, Bottlenecks, and Limitations

Is fouling on an exchanger keeping your process from achieving the production rate it should be capable of meeting? How much additional gas or liquid can be processed

in the current equipment? The ProMax Heat Exchanger Rating utility can help you determine many possible process limitations and assist in finding solutions.

Create an Exchanger Library

Using the ProMax HEX Import and Export options, you can build a library of commonly ordered exchangers, or create an inventory

of what exchangers are on hand for your use. With a simple import command, you can see which exchanger will most closely match

the requirements of your process, or what modifications you may need to make.