Separators

The Separator Sizing package included in ProMax is capable of helping you size both horizontal and vertical separation vessels in a multitude of process conditions, including separators, scrubbers,

knockouts, flash drums, and slug catchers. The methodology focuses on a minimization of mass while achieving the required separation. For most vessel designs, three or fewer values are required for

an initial sizing to be performed in ProMax, thanks to useful default values provided to help you obtain estimated answers quickly. Parameters can then be adjusted to have a separator that will meet

your project requirements, using the most accurate values available.

ProMax includes warnings based on several correlations and papers to help you know if your separator and parameters follow common separation guidelines, or if there are some potential concerns to

research further for your specific case. As always, the ProMax Help includes several references and information to assist in this process, including pre-worked examples for you to examine.

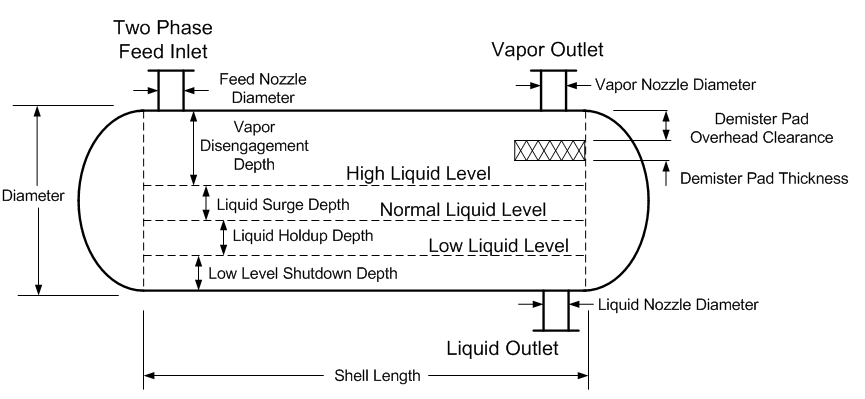

Two-phase Separation

ProMax provides equipment sizing for both vapor-liquid separation and liquid-liquid separation. When selecting between a vertical or horizontal separator, the vapor to liquid ratio and total volume

considerations are important. A vertical separator may be preferred if floor space is at a premium, however the vessel may be required to be larger and more expensive than a horizontal option for

the same gas handling capacity. Horizontal options have a much greater gas-liquid interface area, which is useful in degassing solvents and reducing foaming. Let ProMax help you determine what works

best for your project based on our two-phase separator options:

- Vertical 2-Phase,

- Horizontal 2-Phase.

Three-phase Separation

ProMax provides several options for sizing vessels used in separating three-phase flow, depending on your project specifics. Similar to the two-phase options, the vapor to liquid ratio and total

volume considerations play a large role in which option is most cost-effective. For a three-phase system, however, additional constraints must be examined when selecting the specific type. For example,

although a boot may theoretically decrease the vessel mass and material cost, increased fabrication time and cost, and a higher overhead clearance may negate the advantages. Likewise, consistent operation

requires easily maintained level control, and some types are significantly easier to control than others in many specific cases. ProMax can size:

- Vertical 3-Phase,

- Horizontal 3-PhaseHorizontal 3-Phase with Boot,

- Horizontal 3-Phase with Weir,

- Horizontal 3-Phase with Bucket and Weir,

- Horizontal 3-Phase with Boot and Weir.

Thickness Calculations

Based on ASME Boiler and Pressure Vessel Code, ProMax can help you calculate the estimated required thickness for both two- and three-phase separators under internal pressure.

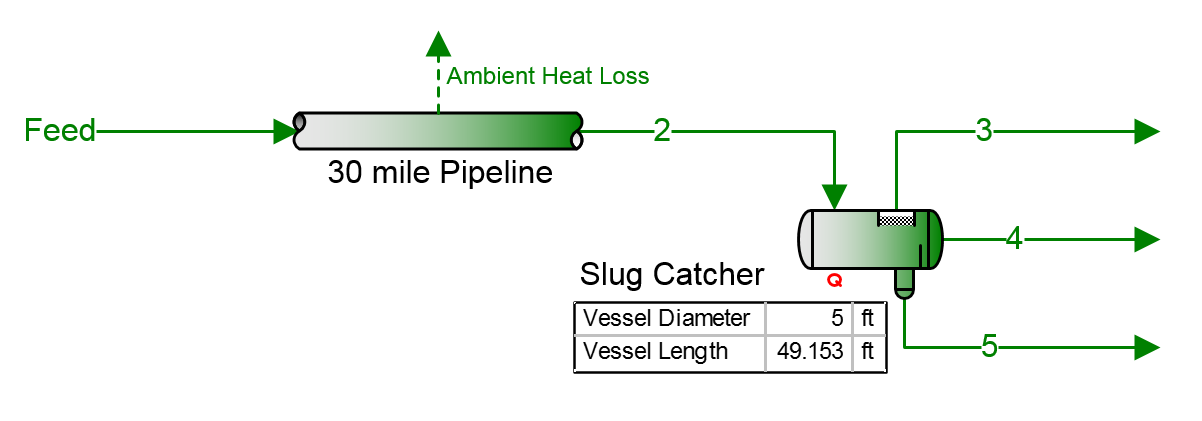

Slug Catcher Sizing

Let ProMax assist in sizing slug catchers based on predicted liquid production and designed periodic pigging of pipelines. ProMax scenarios can be run to optimize the vessel cost

by adjusting the slug catcher vessel inside diameter to recalculate the required length, and for adjusting the flow into multiple parallel vessels. Used in conjunction with the

ProMax Pipelines, our tools can help calculate how much liquid should be expected, and how large the slug catching equipment should be designed.

Rating Existing Equipment

The ProMax Separator Sizing is designed to show the required size for complete and successful separation. If a desired separator is at least the size that ProMax predicts is required,

then there is a high chance of success in utilizing the equipment. To best simulate your current equipment, ProMax solvers may be used to calculate parameters.