Distillation

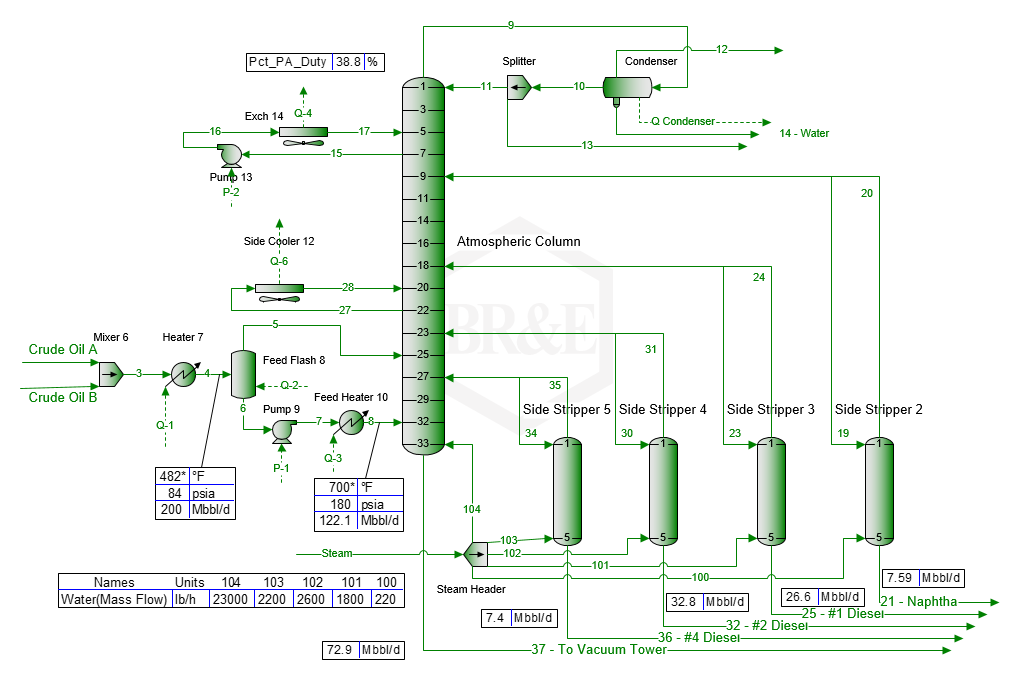

ProMax has the ability to model a variety of fractionation columns in refineries, including crude fractionators (atmospheric and vacuum),

saturated gas plants, coker fractionators, and many others. ProMax capabilities allow users to

- Characterize oils using distillation curves or the Oil Speciation block

- Run simulations with hundreds of components

- Simulate columns using ideal stage models or mass transfer rate-based models

- Add user-defined reaction sets to the column to simulate reactive distillation

- Perform analyses (vapor pressure, distillation curves, etc.) on a per stage basis

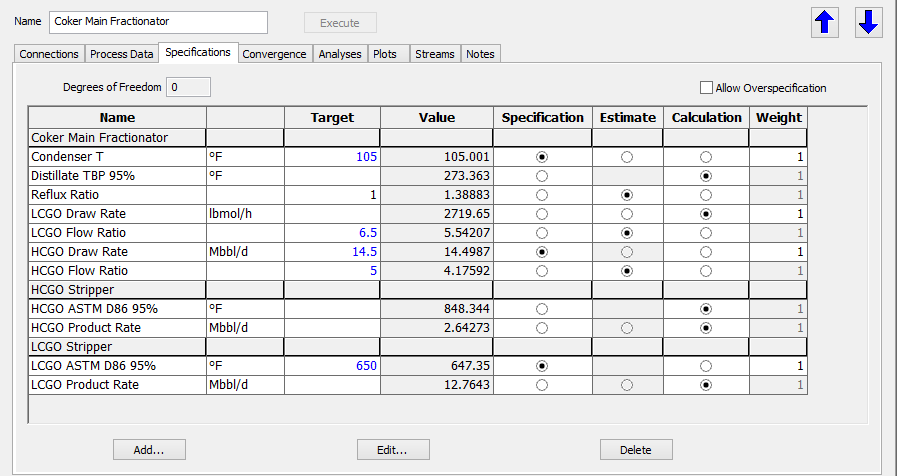

- Control settings and view results for a main column and its side columns all in a single window

- Use specifiers and solvers to customize column specifications (e.g. a specifier to set an overflash of 5%)

- Columns can be configured by setting traditional quantities, like reflux ratio, product rates, and temperatures, or by specifying product quality.

- Side columns can be directly connected to their main column, allowing for the integration of different units, faster convergence times, and better organization. Specifications and calculations for all of the columns may be controlled from the main column’s specification window.

Characterizing Crude Oils

-

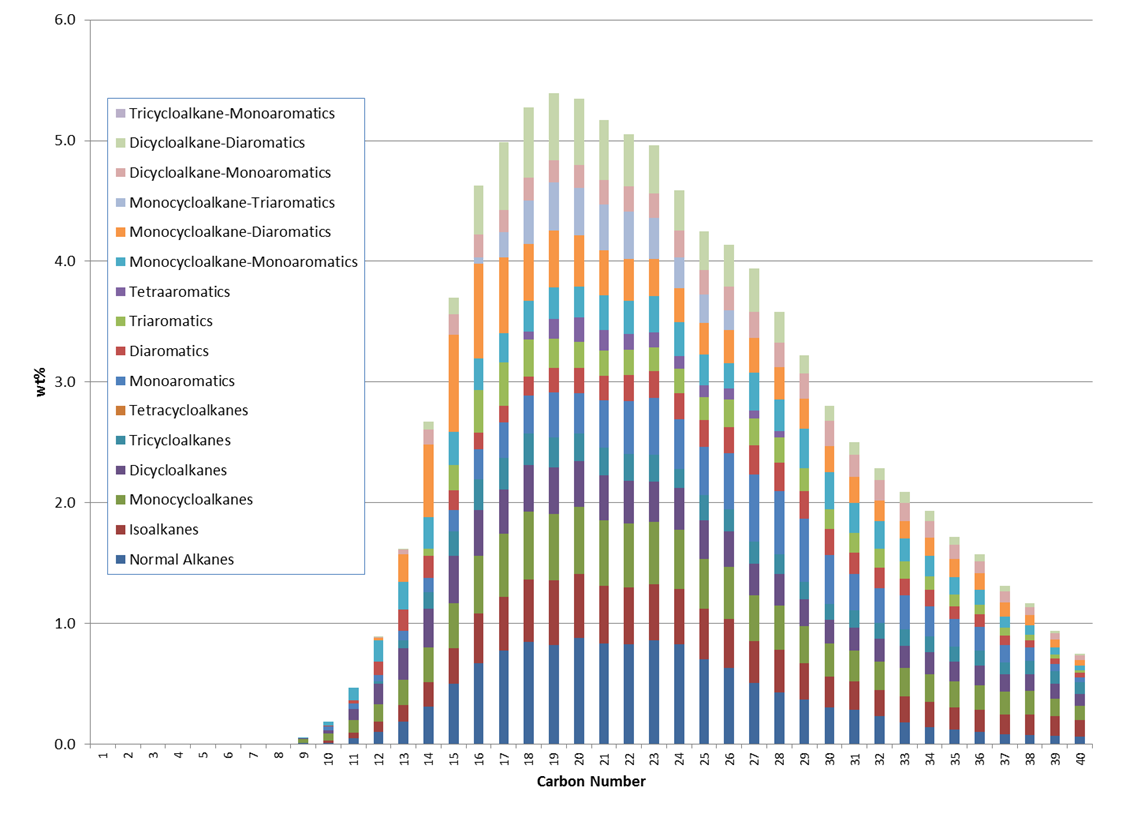

To model a process containing a crude oil or condensate, the properties of the oil must be known or at least estimated. Determining the exact composition

of crude oils and heavy condensates is not feasible because of the enormous number of components included in these mixtures. Instead,

a boiling curve analysis is usually performed by measuring the temperature of the distillate fraction at specific cumulative volume percentages.

These boiling point measurements are then related to the physical properties of the oil or condensate using correlations developed by industry.

The correlations estimate properties such as specific gravity, molecular weight, viscosity, critical temperature and pressure, etc., based on the

crude oil analysis. A crude oil mixture may be modeled as a single component or as a group of hypothetical components which represent the boiling curve

of the crude oil mixture.

Oil Assay

-

A crude oil or condensate may be defined by assay using a boiling curve analysis which usually consists of temperature measurements of distillate

fractions at specific cumulative volume percentages. Other properties such as molecular weight, specific gravity, or viscosity may also be determined

at specific cumulative volume percentages. More commonly, molecular weight and specific gravity are supplied as bulk properties which are measured for

the overall oil sample. These boiling curve measurements and bulk properties are then related to the physical properties of the oil or condensate using

correlations. The more data available, the more accurate the characterization.

Defining a Single Oil

-

The Single Oil characterization is intended to model a narrow boiling mixture as a single component.

-

A Single Oil is ideal for characterizing a C6+ or C7+ fraction of a natural gas for which the average boiling point or molecular weight and specific gravity are known.

Wider boiling mixtures should be characterized using a boiling point curve.

Specifying Light Ends for Oils

-

Light Ends are lower molecular weight organic compounds which can be included as components in the oil.

-

Light Ends can be generated from the boiling curve data, supplied from a separate analysis, or no light ends can be specified.

-

If generated or supplied, the amount of each light end component represents the amount of the oil mixture that has an average

boiling point equal to the specified light end (e.g. the basis for Light Ends Amounts is the same as the original assay data basis).

Example: Pentane and Hexane are specified as light end components, and the generated (or specified) amounts are 11% and 6%, respectively.

This means that 17% of the boiling curve will be replaced by these two components.

-

Oil Blends may also be generated from previously defined oils.

-

Easy to use Oil Speciation Tool to convert assay data into a mixture of compound and pure species.