Hints on Modeling Liquid-Liquid Amine Treaters

Craig Spears

Feb 21, 2013

Some Hints on Modeling a Liquid-Liquid Amine Treater

Many natural gas liquids (NGLs) and liquefied petroleum gases (LPG) contain acid gases (hydrogen sulfide and carbon dioxide) that must be removed; hydrogen sulfide contributes greatly to corrosion, and carbon dioxide can lead to raised vapor pressures and lowered heating values in products. In many cases amines are selected to treat these liquids because of prohibitive costs of caustic solution or mol-sieve operation, especially when a gas amine treater is already onsite and a slipstream of amine from the main unit can be used.

Some General Information on Liquid-Liquid Amine Treating

Almost any amine may be used for liquid treating with satisfactory performance: MEA, DEA, DGA, MDEA, and MDEA-based solvents have been used.

The contact time is very long (generally 30 minutes or longer when including a phase separation step). This extended contact time allows even the relatively slow reaction between CO2 and amines to occur, and also results in a major difference between gas treating and liquid treating. The short residence time in a gas treater creates a situation where the kinetic time limitations are very important and accurate predictions of sweetening require very specific calculations to know the extents of reaction: special care must be taken in simulating these tower types. With liquid treating, equilibrium stages are a good approximation.

For CO2 specifications, often a single theoretical stage can accomplish the necessary sweetening. This can be done with several contacting methods including

static mixers,

jet eductor mixers, or with a distillation column.

For H2S specifications, at least two theoretical stages will normally be required to accomplish the necessary sweetening. This can be done with static mixers or jet eductors, but will require a settling tank between two of these mixers in series. Instead, distillation columns are commonly utilized.

Trayed columns will typically use sieve plates with 1/8”-1/4” perforations for dispersion of the hydrocarbon phase into a continuous amine phase. These drops rise through the amine phase which is flowing horizontally across the plate and then passing to the plate beneath it through the downcomer, with no outlet weir. At least 10 trays have been found to be required to achieve the equivalent of one ideal stage. LPG velocities of greater than about 1.25 ft/s through orifices can produce emulsions and amine carryover while velocities below 0.5 ft/s can lead to LPG entrainment in the amine phase.

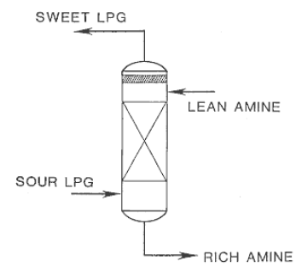

|

Distillation column with one packed section representing one theoretical contact stage

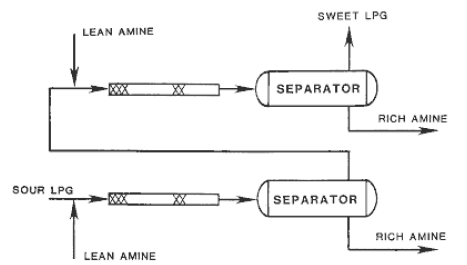

Two-stage static mixer/separator series

|

Packed columns are preferred in many cases for liquid treating. Random packing requires approximately 8 ft of packing for one ideal stage, but one section will rarely exceed one ideal stage; a redistributor should be used after each section to increase the number of stages. Packing diameter should be no larger than 1/8 of the tower diameter, but normally no smaller than ½ inch. Random packed towers tend to have a poor response to varying hydrocarbon flow rates and can also have issues with channeling. Structured packing helps eliminate channeling, allows better mixing and droplet stirring, can have a single unit instead of multiple beds, while also running at a higher capacity.

Full flow amine filtration is recommended in all cases to prevent plugging and decreased efficiency.

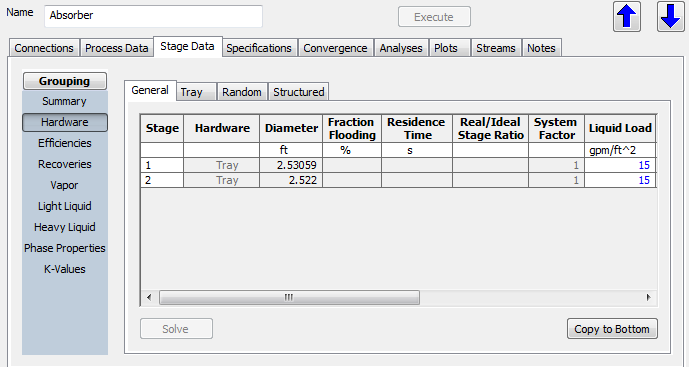

Sizing is often based on the superficial velocity of the two liquid phases combined. For gas plant liquids 15 gpm/ft2 is recommended, and for refinery operations a superficial velocity of closer to 10 gpm/ft2 is recommended because of typical contaminants.

Water wash towers are a common option used downstream to remove entrained water-based treating solutions. A circulation ratio of 10-40% of the hydrocarbon rate should be adequate if good liquid-liquid contact is obtained. The solution concentration in the wash water should not build up to more than 3 weight percent.

|

Liquid Treating in ProMax

Using a 3-phase separator.The simplest method is to connect both the liquid hydrocarbon and the amine feed streams to the separator at the feed location, and then set the pressure drop. The separator will act as a single ideal stage.

|

Using a distillation column.

In the Process Data tab, select an “Equilibrium” column type and a flash type of “LLE”.

Set the pressure profile of the column in the Stage Data -> Summary dialog.

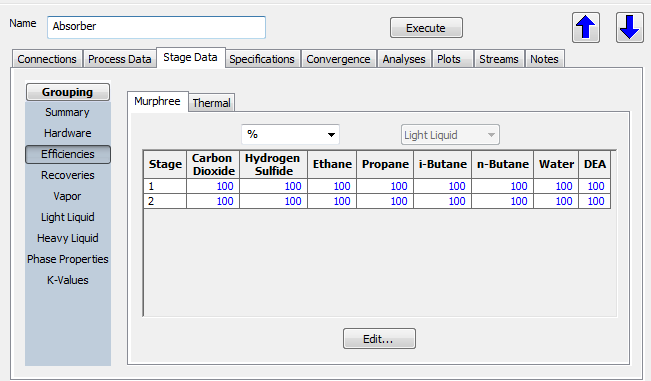

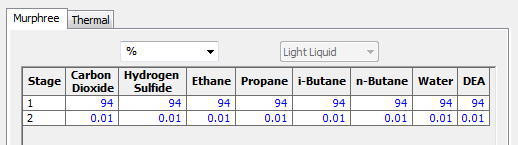

For multiple stages, select the correct number of stages. Typically this will be either two or three stages; very rarely will it be higher. Keep the Stage Data -> Efficiencies settings at 100%, as shown to the right for a 2-stage column.

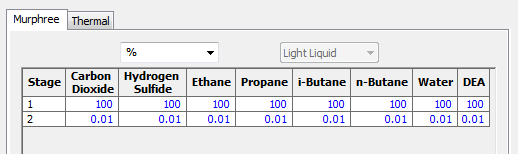

For a single contact stage, use two stages when creating the column. In the Stage Data -> Efficiencies dialog, modify the efficiencies of one stage to be 0.01%. Hint: if the column has difficulties converging, try switching which stage is set to 0.01% efficiencies; sometimes the efficiencies have to be increased to 1% or even 5% for a solution.

For less than a single equilibrium contact stage, create the column with two stages. In the Stage Data -> Efficiencies dialog, modify the efficiencies of one stage to be 0.01% as in the previous case, and change the second stage to the efficiency you wish to model.

The column can be sized based on the superficial velocity (or liquid load). You may set either the diameter of the column to solve for the superficial velocity, or as shown below you may set a desired Liquid Load and find the diameter required.

|

Murphree Efficiency settings for modeling two ideal stages

Murphree Efficiency settings for modeling one ideal stage

Murphree Efficiency settings for modeling a 94% efficient stage

Hardware dialog settings for sizing a liquid column

|

For more information, please see some of our articles here: Technical Articles

This entry specifically uses information from these articles:

Treat LPGs with Amines

Addition of Static Mixers Increases Treating Capacity in Central Texas Gas Plant

Design Alternatives for Sweetening LPGs and Liquid Hydrocarbons with Amines